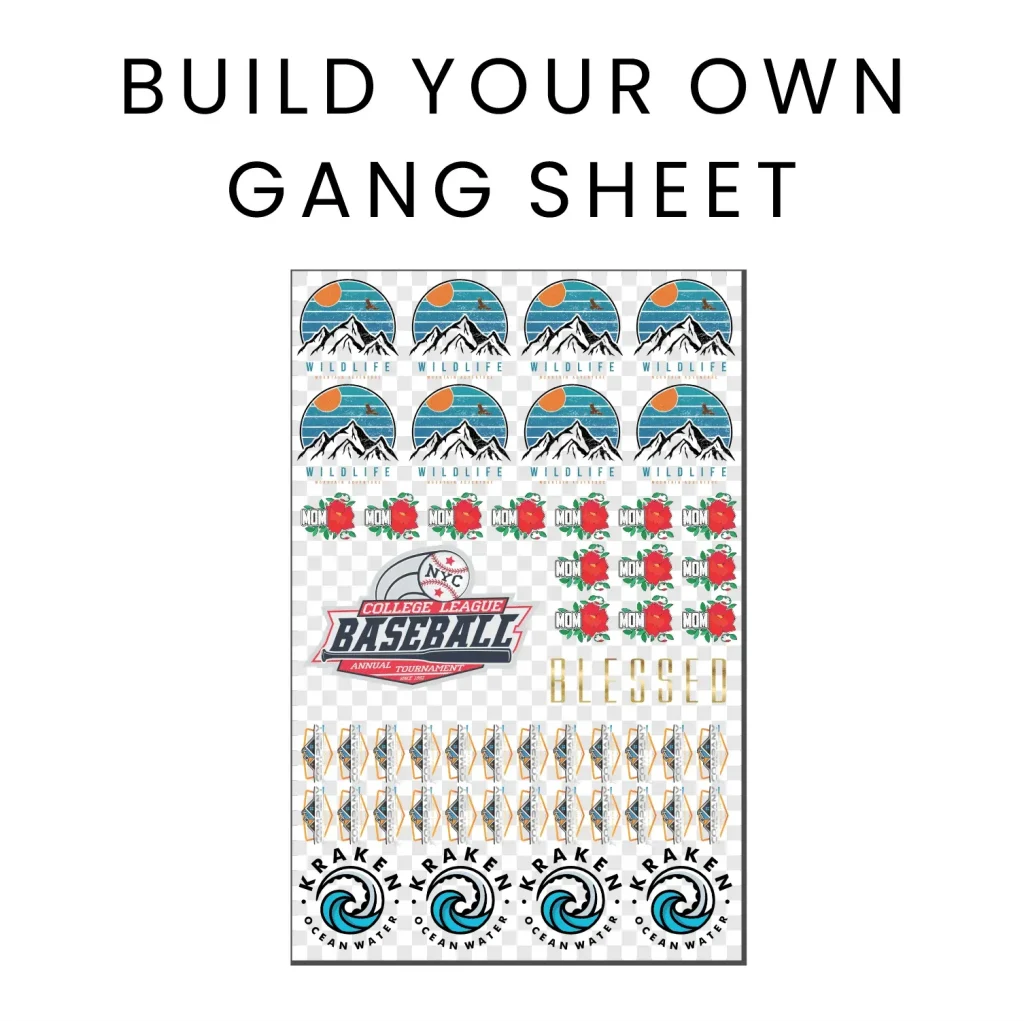

DTF gangsheet builder is transforming how designers and screen printers plan multi-design runs by turning scattered artwork into a cohesive, production-ready sheet that reduces waste and speeds decision-making. By championing seamless design collation, the tool maximizes sheet usage, minimizes misregistration, and delivers repeatable results across varied print runs, with intuitive drag-and-drop placement, snapping to guides, and batch-preflight checks that speed onboarding for new team members. You’ll find practical gangsheet design tips embedded in templates and workflows that align color settings, print zones, and file prep with a consistent DTF printing workflow, while the approach also reduces handoffs and accelerates approvals. This approach supports design consolidation for DTF, helping teams build catalogs, run promotions, and scale production without sacrificing color accuracy or output quality, thereby boosting DTF production efficiency, enabling asset reuse, and improving supplier coordination. With clear planning, fixed grids, and built-in checks, projects move from concept to production with confidence, ensuring faster time-to-market, less rework, and tighter collaboration between design, prepress, and shop floor.

Beyond this specific tool, the concept translates into a layout planner that groups multiple designs on a single transfer sheet, optimizing space and reducing waste. Think of it as a prepress automation approach that blends art, color management, and production scheduling to improve throughput and consistency. LSI-driven terminology helps teams connect ideas like batch design organization, template-driven grids, and scalable production pipelines for garment transfers. Adopting this mindset across operations supports faster approvals, clearer asset management, and a smoother DTF printing workflow, ultimately contributing to higher throughput and lower costs.

Maximizing Efficiency with Seamless Design Collation in DTF Workflows

In DTF printing, seamless design collation is the backbone of a fast, repeatable production process. By arranging multiple designs on a single sheet with consistent margins, anchors, and safe zones, you can dramatically reduce waste and improve turnaround times. This approach also helps standardize how files are prepared, which in turn strengthens the overall DTF printing workflow.

Adopting a seamless design collation mindset means establishing a predictable framework. Start by defining your sheet size, grid, and template family, then reuse these templates across jobs to preserve alignment and color integrity. The result is faster proofs, fewer last-minute edits, and clearer design consolidation for DTF—key factors in boosting DTF production efficiency over time.

DTF Gangsheet Builder: Core Capabilities for Accurate Layouts and Gangsheet Design Tips

A DTF gangsheet builder functions as a centralized planning hub, organizing multiple designs, color separations, and print zones into a single production-ready sheet. This capability directly supports gangsheet design tips by providing a repeatable framework for layout, alignment, and color management, reducing room for human error and speeding up the setup phase.

Leveraging the tool’s automation features—auto-arrange, snap-to-grid, rotation, and mirroring—helps populate sheets quickly while preserving precise spacing. This not only improves the DTF printing workflow but also reinforces design consolidation for DTF as teams can rely on consistent templates and grid rules, even when scaling catalogs or running time-sensitive promotions.

Color Management and Artwork Preparation for a Smooth DTF Printing Workflow

Color management is crucial to ensure that designs look the same on screen and on transfer. Prepare artwork with consistent color settings, ideally using an ICC profile tailored to your DTF printer and transfer materials. Converting to the correct color space before placing designs on the gangsheet helps lock color modes early, preventing shifts during export and reducing reprints in the DTF production process.

By addressing color early, teams can maintain reliable color reproduction across multiple designs on a single sheet. This proactive approach supports a smoother DTF printing workflow and strengthens design consolidation for DTF, because consistent color handling becomes a repeatable part of every job rather than a special case.

Design Consolidation for DTF: Templates, Grids, and Metadata for Reuse

Design consolidation for DTF thrives on standardized templates and fixed grids. Create reusable templates with fixed margins and color profiles so that every design aligns identically across sheets. This practice minimizes layout deviations and supports reliable color reproduction, making it easier to manage multiple designs in a single gangsheet and scale output efficiently.

A robust naming convention and metadata strategy further enhance consolidation. Include job IDs, sheet IDs, design names, and revision numbers in filenames, and embed printer profiles or transfer media references in metadata. This level of organization makes QA and reprints faster and cleaner, directly contributing to DTF production efficiency and smoother end-to-end workflows.

Boosting DTF Production Efficiency with Standardized Grids, Spacing, and Automation

Even with a gangsheet builder, consistent spacing and margins are essential to prevent misregistration. Use a conservative approach to bleeds, maintain fixed gaps between designs, and apply uniform safe zones. Standardized grids reduce layout errors and ensure that every design translates well during the DTF transfer, which in turn supports a more efficient production flow.

Automation features like auto-arrange and grid snapping are force multipliers for large catalogs or time-critical campaigns. They accelerate setup while preserving alignment, and they pair well with templates to maintain a consistent DTF printing workflow. While automation speeds production, always perform a final human check to catch edge cases that algorithms might miss.

Quality Assurance and Preflight: Minimizing Mistakes in DTF Projects

Quality control is the final gate before printing. Implement a standardized QC checklist covering alignment, color accuracy, font readability, and sheet integrity. With a DTF gangsheet builder, you can embed repeatable QC steps into your workflow, ensuring every sheet meets brand and production standards and reducing costly reprints.

A thorough preflight and proofing stage helps catch issues early. Use both digital checks and physical proofs when possible, verifying bleed, margins, color space, and typography in context of the actual transfer media. By integrating robust proofing into the DTF printing workflow, you reinforce seamless design collation and push DTF production efficiency to a higher, more predictable level.

Frequently Asked Questions

What is a DTF gangsheet builder and how can it improve DTF production efficiency?

A DTF gangsheet builder is a design tool that arranges multiple designs on a single sheet, turning a manual layout task into a repeatable workflow. By standardizing templates, grid systems, and color profiles, it boosts DTF production efficiency, minimizes waste, and reduces rework through seamless design collation and consistent alignment across designs.

How does the DTF gangsheet builder support seamless design collation and prevent misregistration?

The builder defines an anchor grid, margins, and safe zones to align designs, enforcing consistent spacing and template use. This centralized layout reduces deviations, improves registration accuracy, and ensures seamless design collation across the sheet.

What are essential gangsheet design tips when using a DTF gangsheet builder?

Gangsheet design tips include using fixed grids and reusable templates, standard color profiles, and clear file naming. Plan spacing and margins to avoid crowding, test sheets before production, and maintain consistent alignment to support a smooth DTF workflow.

How does the DTF gangsheet builder fit into the DTF printing workflow?

In the DTF printing workflow, the gangsheet builder streamlines prepress, auto-arrange, and export steps, enabling better color management and faster proofs. It helps ensure export settings match printer capabilities, contributing to a reliable, repeatable production process.

How can design consolidation for DTF be achieved with a DTF gangsheet builder?

Design consolidation for DTF is achieved by collating multiple designs, color separations, and print zones into one production-ready sheet. This reduces asset fragmentation, standardizes file preparation, and leads to more consistent results across campaigns.

What steps ensure DTF production efficiency when using a DTF gangsheet builder?

Plan the sheet size and grid, adopt standardized templates and templates, enforce color management, run preflight checks, and maintain versioned metadata. Regular QC and proofs catch issues early, helping maintain high DTF production efficiency and predictable outcomes.

| Key Point | Description |

|---|---|

| Plan your sheet upfront | Define final sheet size, margins, bleed, safe zones; set an anchor grid (e.g., 4×3 on a 12×18 gangsheet) to fit all designs and reduce back-and-forth changes, ensuring consistent tile size, margins, and alignment. |

| Standardized templates and grids | Create reusable templates with fixed grids, margins, and color profiles to maintain alignment; simplify rotation, mirroring, or flipping; reduces deviations and supports reliable color reproduction. |

| Color management in advance | Use ICC profiles tailored to printer and transfer material; convert to proper color space; lock color modes early to prevent shifts; reduces reprints. |

| Artwork quality for DTF transfers | Prefer vector formats (AI, EPS) for crisp lines; raster images at 150–300 dpi; consider halftones/gradients; avoid tiny text near print edge to improve transfer accuracy. |

| Spacing, bleed, and margins | Maintain consistent spacing; provide safe margins; use bleed only if printer supports; prevents misregistration. |

| Naming, metadata, and version control | Adopt robust naming; include job IDs, sheet IDs, design names, revisions; metadata links to transfer media/printer profiles; aids QA and reprints. |

| Automation features | Use auto-arrange, snap-to-grid, rotation, mirroring to populate sheet; reduces human error; always perform manual checks for edge cases. |

| Export and verify before printing | Export per printer capabilities; use lossless formats; separate exports for colorways if needed; perform preflight for color space, bleed, margins; proof digitally and physically. |

| Quality control integration | Include QC checklist for alignment, color accuracy, font readability, sheet integrity; build repeatable QC checks into workflow; adjust templates as needed. |

| End-to-end workflow integration | Ensure seamless data handoffs between design, prepress, and production; align with inventory and scheduling; reduces delays and improves throughput. |

| Common pitfalls | Inconsistent grid usage; color mismatches; overcrowded sheets; poor file naming; inadequate proofing. |

| Case Study: Hypothetical gangsheet run | Illustrative example: 12 designs on a 12×18 sheet using a 4×3 grid, consistent color profile, spacing checks, and final proof before printing. |

Summary

DTF gangsheet builder is a strategic tool for achieving seamless design collation and improved DTF production efficiency. This descriptive conclusion highlights how standard templates, color management, spacing, metadata, automation, and end-to-end workflow integration drive consistency, reduce waste, and accelerate time-to-market for DTF projects. By applying best practices outlined in this guide, teams can optimize their DTF printing workflow, enhance design consolidation for DTF, and realize scalable production with greater reliability.