DTF gangsheet builder pitfalls can quietly derail a production run, especially when teams push multiple designs onto a single transfer without precise planning, clear garment templates, or unit-level validation tests that catch misalignments before mass printing. From layout and margin mistakes to color management and export settings, small missteps can cascade into wasted material, inconsistent color reproduction, and unexpected heat-press issues that slow downstream workflow. This introductory guide highlights how to avoid DTF printing mistakes, adhere to DTF gang sheet best practices, and reduce common DTF printing errors by building a repeatable workflow that includes preflight checklists, version control, and cross-checks between design files and output specs, with a focus on optimizing DTF workflow. A strategy based on precise templates, calibrated color profiles, and disciplined file handling minimizes rework, reduces waste, and improves overall repeatability, while also enabling teams to scale production without sacrificing accuracy or fabric compatibility. By prioritizing robust pre-flight checks, standardized workflows, and ongoing documentation, you can transform the risk of these pitfalls into consistent, high-quality prints across fabrics, colors, and run lengths; this disciplined approach also improves onboarding, enables better forecasting, and helps you communicate value to stakeholders.

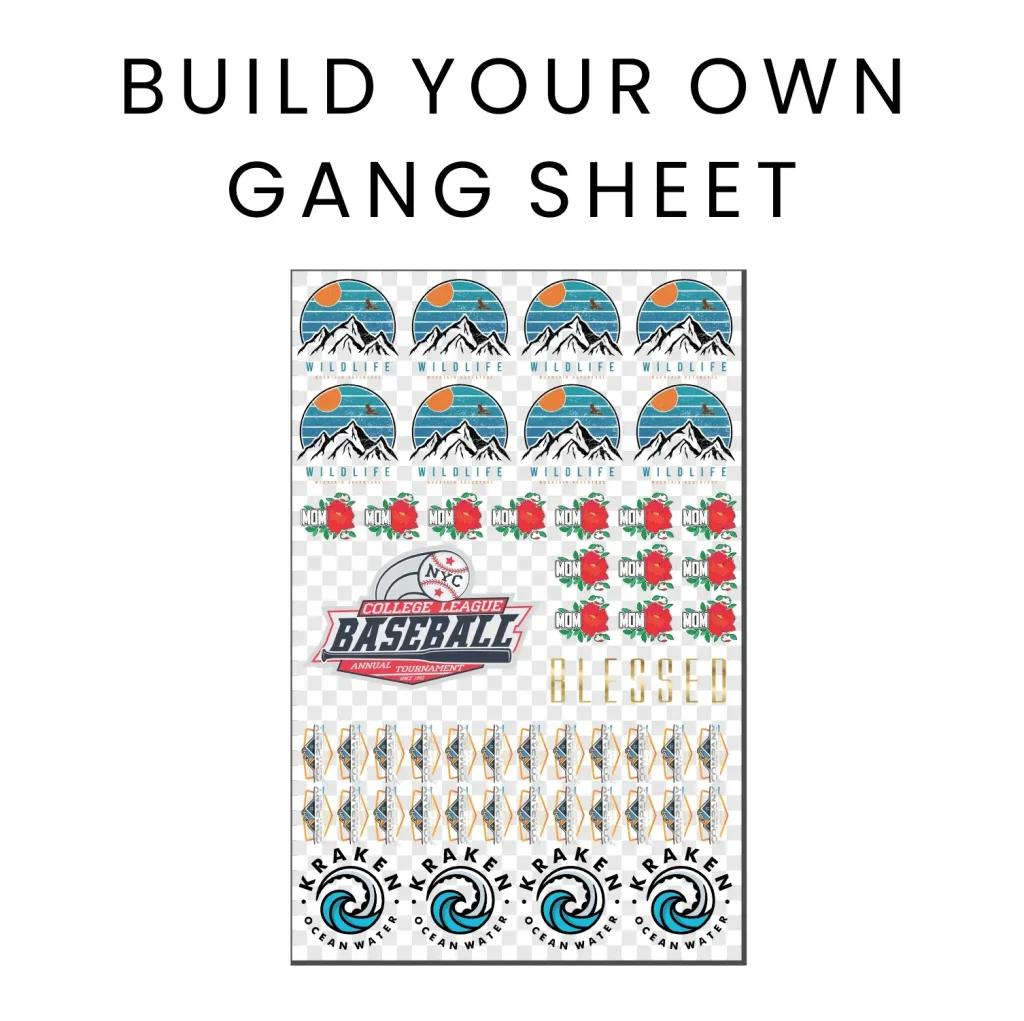

Think of the challenge as arranging designs on a single transfer canvas rather than a single image in isolation. When teams assemble a gang sheet, the focus shifts to layout harmony, margin safety zones, color-consistency workflows, and reliable export pipelines—factors that influence predictability just as much as the layout itself. By describing these issues with terms like multi-design sheet creation, sheet-level alignment, and color calibration discipline, you leverage Latent Semantic Indexing (LSI) to help search engines connect related topics such as reducing printing mistakes and improving overall workflow. In practice, mastering this domain means adopting templates, standardized color profiles, and a repeatable pre-press routine that reduces variance across batches.

DTF gangsheet builder pitfalls: identifying failure modes in the design-to-print workflow

DTF gangsheet builder pitfalls are the subtle mistakes that can multiply when you place multiple designs on a single transfer sheet. Common issues include misaligned grids, inconsistent design scales, and missing margins, all of which can lead to wasted materials and inconsistent results. When these pitfalls occur during the design phase, they often translate into costly reprints and frustrated customers. Understanding these failure modes is the first step toward a smoother, more predictable production run and aligns with the goal of reducing common DTF printing errors.

By recognizing where the gangsheet builder tends to fail—whether in layout arrangement, color management, or export integrity—you set up a framework for preventing mistakes. This approach mirrors best practices in how to avoid DTF printing mistakes, emphasizing deliberate checks and standardized processes. Embracing DTF gang sheet best practices helps teams catch issues early and maintain higher quality across multiple runs.

Precise garment templates and margins to prevent misalignment on gang sheets

Accurate garment templates are critical to ensure that each design prints in its intended location. Using generic or incorrect dimensions can cause designs to crop, shift, or collide when pressed, especially as you move from sample runs to full batches. The risk of misalignment grows when templates do not reflect different garment types, sizes, or printing areas. This echoes the broader idea of how to avoid DTF printing mistakes by anchoring layouts to dependable, garment-specific measurements.

Developing grid-based templates with clear safe zones and margins minimizes layout drift and aligns production expectations with printer capabilities. When you standardize these templates, you not only reduce misplacement but also streamline the workflow, contributing to optimizations in DTF workflow and ensuring consistent results across products.

Color management and calibration for consistent multi-design gang sheets

Color fidelity across multiple designs on a single gang sheet requires a robust color workflow. Without calibrated monitors, printer profiles, and reliable ICC profiles, colors can shift from the digital file to the final print. These color discrepancies are a common DTF printing error that undermines brand consistency and customer satisfaction. Establishing a color management plan helps mitigate this risk and supports more predictable outcomes.

Regular test prints, color targets, and adherence to standardized color profiles help maintain consistency even as you add new designs or fabrics. Linking color accuracy to practical steps—such as profiling, soft-proofing, and device calibration—supports the broader objective of optimizing DTF workflow and reinforces best practices for multi-design gang sheets.

Standardized export pipelines to prevent file integrity issues

Export settings are a frequent source of trouble when they are not standardized. Misaligned color modes, incorrect resolutions, or incompatible file formats can yield low-quality prints or unusable transfers. This is a prime example of how to avoid DTF printing mistakes, because the export step directly influences print fidelity and downstream performance.

Implementing a single, printer-friendly export pipeline—defining CMYK color mode, 300 dpi resolution, and appropriate file formats—reduces ad-hoc errors and syncs with typical DTF gang sheet best practices. Coupling standardized exports with naming conventions and pre-flight checks builds a consistent, scalable workflow that minimizes common DTF printing errors and accelerates production.

Materials compatibility and process controls for reliable transfers

Material choice and process parameters influence transfer quality as much as the design itself. The wrong transfer film, adhesive, or curing settings can cause soft edges, ghosting, or poor adhesion, especially on a busy gang sheet. Recognizing material-related pitfalls is a key part of avoiding common DTF printing errors and achieving repeatable results on different fabrics.

A systematic approach to validating materials and process parameters—for each fabric type—helps ensure consistency from sheet to sheet. This aligns with the broader aim of optimizing DTF workflow by reducing variable factors and embedding material testing and process audits into the standard operating procedure.

Workflow optimization and QC for scalable, repeatable gang sheets

As production scales, batch-based planning and automation become essential. Grouping similar designs, colors, and fabrics into batches reduces setup time per item and lowers the risk of human error. This is central to optimizing DTF workflow and supports the aims of consistent quality across orders.

A strong quality-control (QC) framework, including pre-print checks, post-print inspections, and post-transfer verification, creates a feedback loop that drives continuous improvement. Maintaining versioned archives of layouts, profiles, and material configurations helps teams reproduce successful runs and quickly troubleshoot deviations—an approach that epitomizes DTF gang sheet best practices and long-term operational excellence.

Frequently Asked Questions

What are the most common DTF gangsheet builder pitfalls and how can I avoid them?

Key DTF gangsheet builder pitfalls include template inaccuracies, margin bleed gaps, and inconsistent scaling. How to avoid them:n- Start with precise garment templates that include margins and safe zones.n- Calibrate color workflow (ICC profiles, monitor calibration) to prevent color shifts.n- Lock a consistent export pipeline (CMYK, 300 dpi, correct file format).n- Use version control and a pre-print checklist to catch issues early.n- Run small test layouts before committing to a full batch.

How can I avoid DTF printing mistakes when using a gangsheet builder?

To avoid DTF printing mistakes with a gangsheet builder:n- Verify exact garment dimensions and layout margins before designing.n- Run test layouts to confirm scale and spacing accuracy.n- Calibrate color management and compare prints to color targets.n- Include bleed and safe zones to prevent edge loss.n- Standardize export settings and file naming to prevent mismatches.

What are the DTF gang sheet best practices to prevent pitfalls in the gangsheet builder?

DTF gang sheet best practices focus on consistency and quality:n- Use standardized templates and reusable layouts for multiple runs.n- Plan layouts with grid-based spacing and uniform margins.n- Optimize color separation so multi-design sheets remain legible after transfer.n- Maintain a well-documented, repeatable workflow and version control.n- Invest in regular crew training and process audits.

What common DTF printing errors occur with gangsheet builders, and how can I address them?

Common DTF printing errors include color shifts, misalignment, bleed edge loss, ghosting, and blurry prints. Address them by:n- Rechecking color profiles and alignment marks on every sheet.n- Verifying margins and bleed settings in the layout.n- Ensuring proper curing times and materials compatibility with the fabric.n- Exporting at the correct resolution and format; avoiding over-complex artwork.n- Performing a quick test print to validate the entire workflow.

How can you optimize DTF workflow to reduce DTF gangsheet builder pitfalls?

To optimize DTF workflow and reduce gangsheet pitfalls:n- Establish repeatable batch processes grouped by design/color/fabric.n- Automate repetitive tasks like file naming, color profiling, and layout generation where possible.n- Implement robust QC at pre-print, post-print, and post-transfer stages.n- Maintain versioned archives of layouts and material configurations.n- Prioritize safety and machine maintenance to minimize downtime and preserve quality.

What pre-flight checks help prevent DTF gangsheet builder pitfalls during export and file handling?

Pre-flight checks to prevent DTF gangsheet builder pitfalls include:n- A pre-flight checklist covering garment size, margins, bleed, color profile, and file integrity.n- Verifying export settings (CMYK, 300 dpi, correct file format) and color management.n- Ensuring consistent version control and file naming to avoid outdated files.n- Conducting a test print or dry run before full production.n- Maintaining a change log to track issues and fixes for future runs.

| Topic | Key Points | Practical Takeaways |

|---|---|---|

| DTF gangsheet basics | – A gangsheet places multiple designs on one transfer sheet to maximize print runs. – The DTF gangsheet builder is the tool used to arrange designs, set spacing, and generate the final print file. – It’s a powerful workflow, but small errors can multiply when scaling production. | – Understand the gangsheet concept. – Identify your builder’s capabilities. – Plan margins and spacing to avoid crowding. |

| Common pitfalls | – Inaccurate garment dimensions and margins. – Design scale and spacing errors. – Color management and profiles issues. – Bleed, safe zones, and margins miscalculation. – File export and integrity problems. – Material and powdering mismatches. – Layout inefficiency. – Version control and file naming chaos. |

– Create precise garment templates. – Run test layouts for scaling and margins. – Calibrate color workflows and profiles. – Enforce bleed and safe zones. – Standardize export settings (color mode, resolution). – Validate materials and processes. – Plan efficient layouts. – Implement consistent naming/version control. |

| How to avoid pitfalls | – Start with precise garment templates. – Calibrate scaling and spacing in the builder. – Implement a robust color workflow. – Enforce bleed and safe-zone rules. – Standardize export settings. – Choose compatible materials and processes. – Plan layouts for efficiency. – Implement clear version control and file naming. – Create a pre-print checklist. – Build in a quality-control loop. |

– Use templates and test prints. – Verify color profiles and margins before production. – Lock export pipelines to avoid ad-hoc errors. – Maintain a pre-print QC checklist. |

| Best practices | – Adopt DTF gang sheet best practices. – Use standardized templates and reusable layouts. – Optimize color separation for multi-design sheets. – Keep a well-documented workflow. – Invest in training and process audits. |

– Develop standardized, reusable templates. – Ensure color separations remain readable across the sheet. – Document the workflow and train staff. |

| Troubleshooting | – Color shifts and misalignment. – Bleed issues and edge loss. – Ghosting or incomplete curing. – Blurry or pixelated prints. – Print-head or roller chatter. |

– Revisit color profiles and alignment marks. – Re-check margins and bleed settings. – Verify curing times/temperature and adhesive compatibility. – Export at correct resolution; adjust art complexity. – Maintain printers and conveyors. |

| Workflow optimization | – Establish repeatable batch processes. – Automate file naming, color profiling, and layout generation where possible. – Build robust QC steps at each stage. – Maintain versioned archives of layouts and material configurations. – Prioritize safety and routine maintenance. |

– Batch similar designs to streamline setup. – Automate repetitive tasks to reduce errors. – Implement continuous QC and archive successful configurations. |