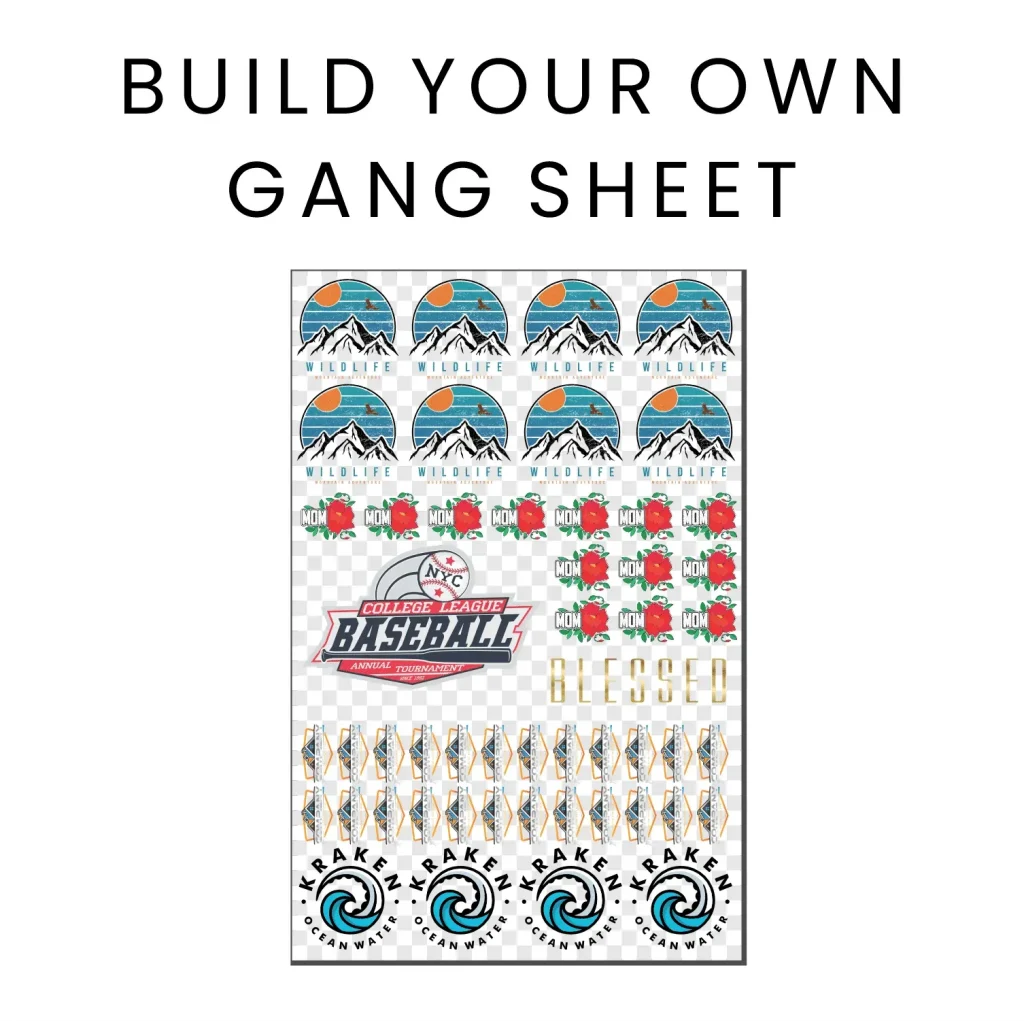

The DTF Gangsheet Builder is transforming the landscape of custom apparel printing by offering innovative solutions for design organization and optimization. This specialized software allows businesses to harness the power of DTF technology, maximizing efficiency while minimizing costs associated with producing intricate designs on fabric. With the rise of DTF printing, gangsheet software has become essential for those looking to streamline their apparel printing processes. By enabling users to create layouts that accommodate multiple designs on a single sheet, these tools optimize both space and print output, making them invaluable in today’s competitive market. As we delve deeper into the world of DTF gangsheet building, we will uncover the features and advantages that this technology brings to the forefront of print optimization.

In the rapidly evolving realm of custom clothing production, Direct-to-Film software tools have emerged as game changers for printers and designers alike. These gangsheet creators facilitate the placement of various artworks onto a single transfer film, enhancing efficiency and saving valuable resources. With the increasing demand for high-quality prints and the necessity for organizations to keep up with bulk orders, such innovative solutions are critical for success in the apparel printing industry. The combination of DTF technology and sophisticated gangsheet building applications allows for a streamlined production process that maintains quality while reducing costs. Join us as we explore the intricacies of these advanced tools and their impact on the future of fabric decoration.

The Evolution of DTF Printing Technology

DTF printing has undergone remarkable transformations over the past few years, advancing from basic functionalities to a sophisticated method that meets the demands of modern apparel production. This evolution is marked by significant improvements in digital ink formulations that deliver superior adhesion and extraordinary color vibrancy. These advancements not only improve the overall aesthetic of printed garments but also enhance their durability, allowing them to withstand repeated washes without fading. As businesses seek to provide high-quality products, the role of DTF technology in setting new standards becomes increasingly vital.

In recent times, DTF printing solutions have incorporated cutting-edge technologies, such as eco-friendly inks and faster curing processes. This shift not only addresses environmental concerns but also caters to a growing consumer preference for sustainable apparel options. The use of state-of-the-art equipment ensures that companies can achieve high output levels without compromising on quality or eco-responsibility, making DTF printing a sustainable choice in the competitive world of custom apparel.

Exploring DTF Gangsheet Builder Functionality

DTF gangsheet builders are designed with user efficiency at the forefront. These specialized software tools simplify the often-complex task of arranging multiple designs on a single film sheet, greatly enhancing production workflows. By optimizing design layouts, users can minimize material waste and maximize print efficiency, directly impacting the bottom line for businesses. The intuitive interfaces of these tools make it easy for even newcomers to the printing industry to approach gangsheet creation confidently.

Additionally, many DTF gangsheet builders come equipped with features that allow for easy resizing, rearrangement, and customization of designs, streamlining the printing process. This capability not only saves time but also reduces the likelihood of errors during the transfer process. As a result, the integration of gangsheet software becomes indispensable for businesses looking to optimize their apparel printing operations and improve turnaround times.

Key Advantages of Using Gang Sheets in Apparel Printing

Utilizing gang sheets in apparel printing significantly contributes to cost reduction and resource optimization. By fitting multiple designs onto a single film sheet, businesses can efficiently use their materials, reducing waste and thereby cutting down on overall printing costs. This technique is especially beneficial for bulk orders, where maximizing sheet usage directly translates to increased profits. Companies can evaluate design placement strategically, ensuring the best use of space on each gang sheet.

Moreover, gang sheets facilitate faster production times, as multiple designs can be printed simultaneously. This increased throughput allows printers to meet tight deadlines and cater to higher demand without compromising quality. As the apparel industry becomes more competitive, the ability to deliver high-quality custom products quickly will often determine a company’s success, making the advantages of gang sheets more relevant than ever.

The Role of Software in Optimizing Print Processes

Software solutions tailored for DTF printing are paramount in optimizing print processes. By leveraging advanced algorithms and user-friendly features, these tools create a seamless experience for designers and printers alike. For instance, DTF gangsheet builders can automatically calculate ideal layouts, ensuring that every inch of the film is used efficiently. This level of optimization not only reduces material costs but also shortens production cycles, making business operations more agile.

In addition, contemporary gangsheet software often includes options for integrating color management and print quality control, streamlining the entire printing workflow. By providing designers with tools to manage colors accurately and edit designs with precision, these software solutions enhance the quality of the final product. As such, the right software plays an instrumental role in elevating the standards of DTF printing across the apparel industry.

Market Trends Shaping DTF Printing Adoption

The rise of demand for personalized apparel continues to drive the adoption of DTF printing technologies. With consumers seeking unique styles and custom designs, businesses are compelled to invest in more adaptable printing solutions. DTF’s versatility appeals to various segments within the apparel industry, from streetwear brands to promotional merchandise companies looking for an edge in a crowded market. This surge in interest is encouraging manufacturers to explore DTF technology and its offerings of reduced costs and enhanced quality.

Furthermore, as digital printing technologies advance, businesses are increasingly inclined toward solutions that support sustainable practices. The eco-friendliness of water-based inks and the absence of harmful chemicals in the DTF printing process resonate with environmentally-conscious consumers. Keeping pace with these market trends is essential for businesses that wish to thrive, as aligning products with consumer values can substantially impact purchasing decisions.

Integrating Creative Design with DTF Printing

The fusion of creative design with DTF printing technologies unlocks a world of possibilities for apparel manufacturers and designers. DTF printing is particularly favorable for complex and colorful designs, allowing artists to experiment without the constraints often found in traditional printing methods. The DTF technique enables high-resolution outputs that bring intricate graphics to life, captivating consumers and setting brands apart from competitors.

Moreover, DTF gangsheet builders facilitate creativity by providing tools that allow for easy manipulation and layering of designs, encouraging designers to push their artistic boundaries. This capability ensures that businesses can not only meet but exceed customer expectations by offering unique and customizable products. As the demand for personalization grows, understanding how to leverage DTF technology effectively will be crucial for creative professionals aspiring to thrive in the apparel industry.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance DTF printing?

The DTF Gangsheet Builder is a specialized software that helps users efficiently organize multiple designs on a single film sheet for Direct-to-Film (DTF) printing. By utilizing this tool, businesses can optimize space, reduce waste, and lower printing costs, ultimately enhancing productivity in the apparel printing process.

How does the DTF Gangsheet Builder contribute to print optimization in custom apparel production?

The DTF Gangsheet Builder contributes to print optimization by allowing designers to create custom layouts that maximize the use of each film sheet. This meticulous arrangement helps in minimizing material waste and improving cost efficiency, making it an essential component in the DTF printing workflow.

What are the advantages of using DTF technology with a Gangsheet Builder for apparel printing?

Using DTF technology in conjunction with a Gangsheet Builder ensures high-quality prints, vibrant colors, and durability of designs. It allows for intricate artwork to be efficiently printed in bulk, reducing costs and production time while catering to the growing demand for custom apparel.

Can I use software like Photoshop for DTF gangsheet building?

Yes, software like Photoshop can be used for DTF gangsheet building. While not specifically designed for this purpose, it offers precise control over design layouts, allowing users to manually arrange their artwork efficiently for printing. However, dedicated software may offer enhanced features specifically tailored for DTF printing.

What recent developments in DTF technology are impacting the usage of gangsheet software?

Recent developments in DTF technology, including advancements in ink formulations and user-friendly software solutions, have significantly impacted gangsheet software usability. Innovations such as improved adhesion properties and automatic layout features in gangsheet builders streamline the production process, making DTF printing more accessible and efficient.

How does utilizing a DTF Gangsheet Builder affect printing costs for apparel manufacturers?

Utilizing a DTF Gangsheet Builder lowers printing costs for apparel manufacturers by optimizing the arrangement of designs on film sheets. This efficient use of materials reduces waste and maximizes output, allowing businesses to take advantage of bulk printing without incurring additional expenses.

| Key Point | Details |

|---|---|

| Understanding DTF Printing | Combines digital inkjet printing with a transfer process for high-quality, durable prints. |

| Concept of Gang Sheets | Organizes multiple designs on one film to reduce waste and print costs. |

| Recent Developments in DTF Technology | Advancements in ink formulations and user-friendly software enhance production efficiency. |

| Popular Software Options | Includes Photoshop, GangSheet Creator, Printful, and Printify which simplify gang sheet creation. |

| Market Insights | Growing demand for custom apparel drives investments in DTF systems and gang sheet building. |

Summary

DTF Gangsheet Builder is a crucial tool in the custom apparel production landscape, enabling businesses to optimize their printing processes. This innovative technology has revolutionized the way designs are printed on fabrics, providing high-quality outputs and reducing costs through efficient gang sheet organization. As the DTF printing landscape continues to evolve with advancements in ink formulations and software, staying updated with the best practices for gang sheet creation is vital for businesses looking to enhance their productivity. The ever-increasing popularity of DTF printing makes understanding and utilizing DTF gangsheet builders essential for success in the competitive custom apparel market.