The DTF Gangsheet Builder is transforming the landscape of apparel printing by merging advanced technology with creative design possibilities. This innovative tool enhances Direct to Film (DTF) printing by allowing users to create intricate gang sheets that maximize material use and reduce waste. With DTF printing techniques becoming increasingly popular among designers and manufacturers, the ability to efficiently organize multiple designs on a single film sheet leads to cost savings and improved turnaround times. Additionally, integrating sustainable printing practices into the workflow not only meets customer demand for environment-friendly options but also enhances the overall quality of print output. In this article, we’ll delve into expert strategies and tips for effectively utilizing the DTF Gangsheet Builder to elevate your printing potential.

In the realm of custom garment production, the relevance of innovative software solutions such as the DTF Gangsheet Creator cannot be overstated. This cutting-edge application facilitates the process of applying Direct to Film printing methods to a myriad of fabric types, delivering vibrant and durable designs. By mastering gangsheet composition, users are better equipped to handle complex print jobs with efficiency and precision. Moreover, as the demand for personalized apparel grows, exploring alternative techniques associated with DTF—such as advanced layout strategies and eco-friendly printing processes—becomes essential for businesses striving to remain competitive. Join us as we explore various aspects of creating optimal gang sheets that not only satisfy design requirements but also promote sustainable and efficient production methods.

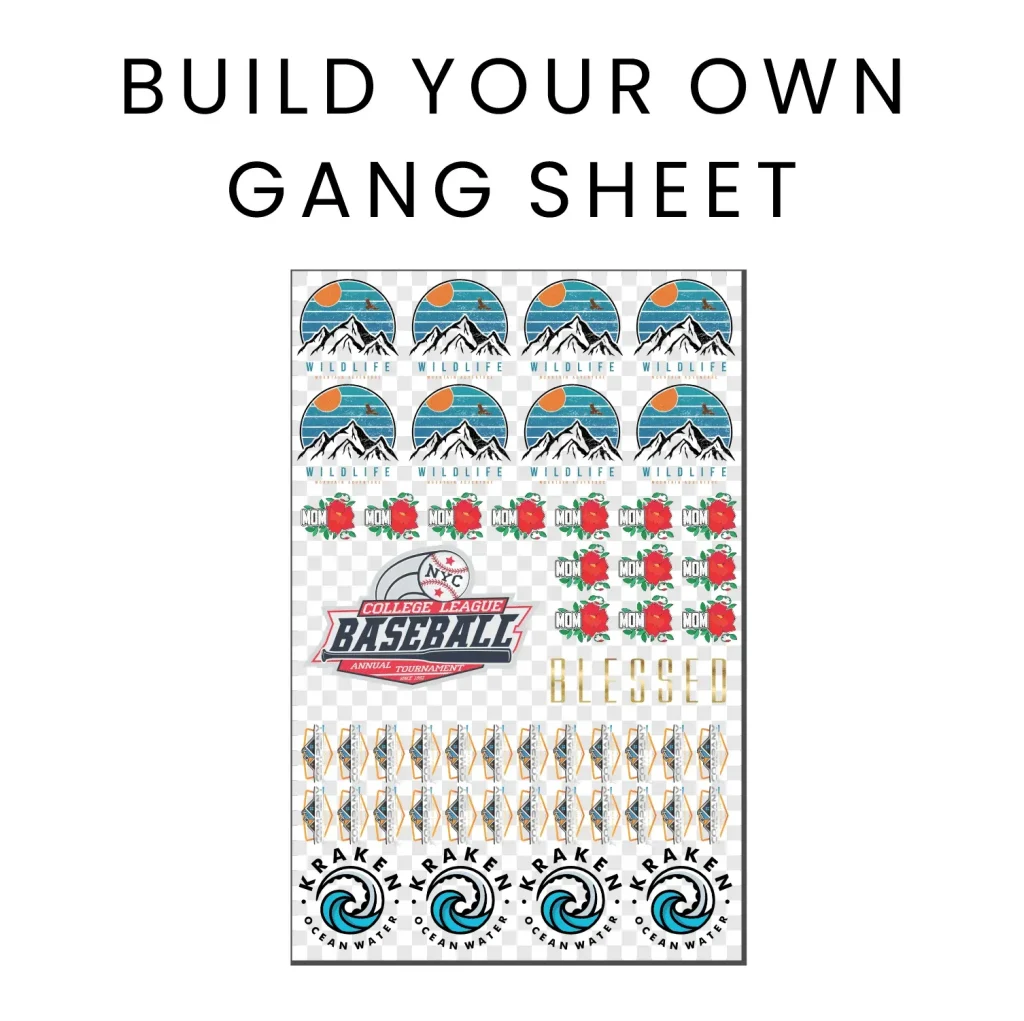

Maximizing Efficiency with DTF Gangsheet Builder

The DTF Gangsheet Builder is an innovative tool designed to enhance the operational efficiency of direct to film printing. By consolidating multiple designs onto a single sheet, this tool significantly reduces both waste and production costs. This gives businesses a competitive edge, particularly in the custom apparel market where timeliness and cost-effectiveness are paramount. Additionally, the gangsheet creation process becomes more streamlined, allowing print operators to focus their efforts on design quality rather than manual layout adjustments.

Integrating DTF Gangsheet Builder into your workflow not only optimizes material usage but also enhances the consistency of printed results. With the ability to produce high-quality images at lower costs, businesses can increase their production volume without compromising artwork integrity. As demand for personalized apparel continues to rise, utilizing this innovative tool becomes a decisive factor in satisfying diverse customer requests efficiently.

Understanding DTF Printing Techniques

Direct to Film (DTF) printing techniques represent a significant advancement in the printing industry, allowing for vivid colors and exceptional detail that can adhere to a wide variety of fabric types. DTF technology works by printing designs onto special film that is later transferred onto textiles with heat and pressure. The sophistication of DTF printing techniques ensures that brands can maintain high quality during the production process while enjoying reduced ink consumption compared to traditional methods.

Furthermore, DTF printing methods have evolved to include various optimization strategies, such as color management systems that guarantee the accuracy of color reproduction throughout different printing jobs. This systematic approach not only enhances the final product’s appearance but also streamlines the workflow, making DTF printing a preferred option for many apparel businesses striving to stand out in a crowded market.

Effective Gangsheet Creation Strategies

Creating an effective gangsheet is critical to maximizing the utilization of Direct to Film materials. One of the key strategies involves precisely arranging multiple designs on a single transfer film, ensuring that each design maintains its integrity and visibility. By employing grid layouts and strategic scaling, printing businesses can accomplish layouts that optimize the available space, allowing for more designs to be printed simultaneously, thus cutting down on material waste.

Additionally, fostering a keen understanding of the software tools available for gangsheet optimization can revolutionize the creation process. For example, specialized DTF printing software offers unique capabilities that automate design placements, making the workflow more efficient and user-friendly. Operators can produce intricate gang sheets more swiftly, which ultimately leads to quicker turnaround times for customers eager for personalized designs.

The Importance of Advanced Software Tools

Advanced software tools play a pivotal role in enhancing the DTF printing process, transforming gangsheet creation into a seamless task. Utilizing programs such as Adobe Illustrator or specialized DTF printing software allows designers to achieve high levels of customization, ensuring that their gang sheets are both visually appealing and optimized for printing. These tools also include functionalities that assist in color management and file preparation, crucial for maintaining consistency across varied printing projects.

Moreover, automation features within DTF-focused software simplify the design process further by analyzing images and suggesting the best arrangements for gangsheet layouts. This reduces the time spent on tedious manual tasks, enabling quicker production cycles that can effectively respond to client demands. As more companies recognize the benefits of leveraging technology in DTF printing, advanced software tools are becoming indispensable in promoting operational efficiencies and creative control.

Sustainability in DTF Printing Practices

Sustainability is increasingly influencing printing practices in the garment industry, and DTF printing technology aligns well with these eco-friendly goals. This method minimizes waste during both the printing and application processes, therefore appealing to eco-conscious consumers and businesses alike. By adopting DTF gangsheet builders, companies not only reduce their carbon footprint but also contribute to a growing industry movement towards sustainable printing practices.

Moreover, as brands strive to meet consumer preferences for environmentally-friendly options, adopting sustainable DTF printing methodologies can prove beneficial. The reduced ink and energy consumption associated with DTF methods enhances an organization’s green credentials while maintaining high-quality production standards. This positions businesses favorably in the marketplace, allowing them to attract a dedicated customer base that prioritizes sustainability.

Continuing Education for DTF Printing Success

To leverage the full potential of DTF printing and gangsheet builders, continuous education is vital. Numerous online platforms provide resources, workshops, and tutorials that cover the latest tips, techniques, and advancements in DTF technology. By participating in these training sessions, printing professionals can stay updated on best practices and emerging technologies that can further enhance their operational effectiveness.

Additionally, investing in training for teams can lead to a culture of innovation within a printing business. Encouraging staff to explore new concepts in design software and printing techniques will not only improve individual skills but also elevate the overall quality of production. Ultimately, staying informed and adaptable in a fast-changing industry ensures that businesses can fully harness the advantages of DTF printing practices, including efficient gangsheet creation.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it enhance Direct to Film printing?

The DTF Gangsheet Builder is a specialized tool used in Direct to Film (DTF) printing that allows users to create multi-design layouts on a single transfer film sheet. By optimizing space through effective gangsheet creation, the builder enhances efficiency, reduces material waste, and streamlines the printing process.

How do I optimize my designs when using a DTF Gangsheet Builder?

To optimize your designs with a DTF Gangsheet Builder, focus on scaling images and utilizing a grid arrangement. Adjust designs to fit multiple layouts on one sheet, ensuring they remain clear and impactful, while the grid helps organize placements systematically to avoid overlaps.

What software is best for DTF printing techniques with gangsheet creation?

For effective gangsheet creation in DTF printing, Adobe Illustrator is a popular choice due to its layout customization capabilities. Additionally, specialized DTF printing software, like Pixie, offers tailored tools for automating design layouts, making the process faster and more efficient.

What printer settings should I consider when using DTF Gangsheet Builders?

When using DTF Gangsheet Builders, it’s critical to configure your printer settings correctly. Ensure high DPI (dots per inch) for sharp images, check film compatibility for thickness, and calibrate temperature and pressure to guarantee successful adherence of designs during the transfer process.

How does DTF printing support sustainable printing practices?

DTF printing supports sustainable printing practices by minimizing material and ink waste. The DTF Gangsheet Builder allows manufacturers to efficiently produce multiple designs on fewer sheets, aligning with eco-friendly business ethics while catering to the rising consumer demand for sustainability.

What resources are available for learning DTF printing techniques and utilizing gangsheet builders?

Numerous resources are available for mastering DTF printing techniques and gangsheet builders, including online tutorials, workshops, and webinars offered by industry organizations. Engaging in these educational opportunities can greatly enhance your skills and application of DTF technology in your operations.

| Key Points | Details |

|---|---|

| Maximizing Printing Potential | Utilize DTF gangsheet builders to enhance your printing capabilities with vibrant and high-resolution designs. |

| Understanding DTF Technology | DTF printing transfers designs onto fabrics using heat and pressure, producing bright colors and intricate details. |

| What is a Gangsheet? | Gangsheet refers to multiple designs placed on a single transfer film, optimizing material use and reducing waste. |

| Layout Optimization | Strategies include scaling images effectively and organizing designs in a grid layout for space maximization. |

| The Role of Software Tools | Use of software like Adobe Illustrator and specialized DTF software improves gangsheet creation and design efficiency. |

| Printer Configuration | Proper DPI settings, compatibility with DTF films, and calibration of temperature and pressure are essential for quality output. |

| Emerging Market Trends | Focus on production efficiency and sustainability aligns DTF printing with modern business ethics and customer demand. |

| Training and Resources | Ongoing training and accessible resources are vital for mastering DTF printing and keeping up with trends. |

Summary

DTF Gangsheet Builder offers unrivaled opportunities for businesses seeking to enhance their printing operations. By leveraging the powerful functionalities of DTF gangsheet builders, companies can significantly optimize their workflows, improve their output quality, and reduce material waste. Embracing strategies such as layout optimization, utilizing expert software tools, and effectively configuring printers are all essential steps in maximizing printing potential. Furthermore, staying informed about market trends and sustainability practices enhances competitiveness and meets evolving consumer demands. Investing time in training and education will ensure businesses adapt well to industry changes, making DTF Gangsheet Builder a pivotal component in the growth of printing enterprises.