DTF transfer by size is a practical approach to achieving consistent, high-quality prints across a range of garments, from adult tees to kids’ shirts and bags. By tailoring the print area to each garment’s measurements, designers improve color fidelity, edge sharpness, and durability while aligning with DTF printing tips. This introductory guide focuses on size-aware design, precise DTF transfer settings, and careful finishing to minimize waste and reworks, while outlining DTF heat press timing considerations to stay consistent. Templates for multiple sizes and scalable artwork help cover DTF transfer sizes across small, medium, and large garments, keeping safe margins and critical details intact. A disciplined workflow—with size-based presets, documented platen temperature, time, and pressure—drives repeatable results and supports DTF design optimization for a professional, customer-ready brand experience.

In other terms, the concept translates to size-aware printing on textiles, where the available print area varies by garment and must be matched with appropriate heat, dwell, and pressure strategies. Viewed through an LSI lens, the idea becomes scaling artwork to fit multiple product dimensions, using size-specific templates and processes that preserve density and edge quality. By planning print areas and press settings around different sizes, you can reduce waste, minimize reworks, and better serve multi-size orders with consistent results.

1) DTF Transfer by Size: Mapping Print Areas to Garment Categories

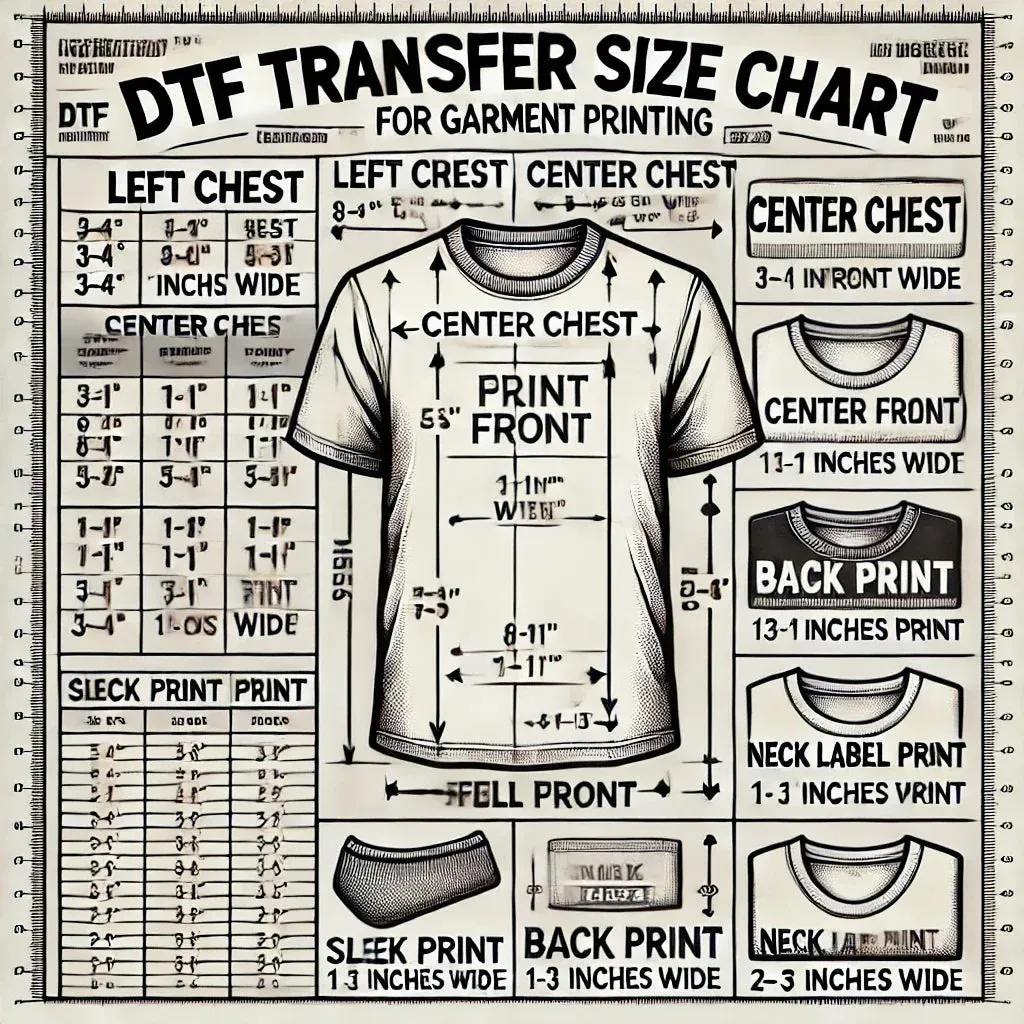

Begin by defining the exact print area for each product before you open your design software. Measuring the maximum printable zone per garment helps prevent crowding on smaller sizes and edge-to-edge issues on larger ones. This size-aware approach is the core of DTF transfer by size, enabling you to design with specific dimensions in mind rather than forcing one footprint onto every product.

Develop templates for size categories (S, M, L, XL, etc.) or use scalable vector artwork that preserves detail as it grows or shrinks. Maintain a safe bleed area so critical elements stay inside the printable region. This practice aligns with effective DTF printing tips and sets a reliable foundation for consistent results across diverse garment types.

2) Maintaining Image Quality Across Sizes: Resolution, Vectors, and Color Management

The visual integrity of your transfer hinges on artwork resolution and vector quality. For DTF printing tips, target high-resolution raster images (ideally 300 dpi at the final print size) and scalable vectors for text or shapes that may be enlarged. Larger transfers can appear washed out if contrast is too light, so plan for bold density and clear legibility across sizes.

Use color management to preserve density as designs scale. Generate size-optimized variants and test print swatches for each category. Keeping color profiles consistent (such as sRGB or Adobe RGB) reduces shifts when designs are resized, a key element of successful DTF design optimization and reliable multi-size production.

3) Size-Based Transfer Settings: Temperature, Time, and Pressure

Establish a presets system that tailors heat, time, and pressure to each size. Larger transfers may need longer dwell times to ensure even adhesion, while smaller ones can benefit from adjusted pressure to prevent edge curling. Document exact parameters for each size: platen temperature, dwell time, and pressure, along with garment fabric and barrier layers.

This disciplined approach reflects the broader DTF transfer settings framework and supports repeatability across batches. Include post-press considerations like cold or hot peeling, and remind staff to log any deviations. Aligning these settings with DTF heat press timing principles helps maintain consistency from one print run to the next.

4) Uniform Coverage Techniques: Pressure, Platen Alignment, and Large Transfers

Uniform pressure is crucial when handling larger designs. Uneven pressure can cause ink gaps, waviness, or edge distortions. If your current platen is a bottleneck, consider a larger platen or a multi-step pressing method to maintain even contact across the entire design area.

Practical tactics include preheating to reduce moisture tension, using teflon or parchment to distribute heat, and adding silicone pads if your equipment supports them. When a larger platen isn’t available, plan sequential presses that cover the design in sections while preserving consistent temperature and pressure. This directly ties to DTF transfer sizes and the need for size-aware pressability.

5) Pre-Press, Moisture Control, and Fabric Selection by Size

Moisture and fabric behavior interact with transfer size to influence bonding quality. Pre-press time should vary with size and fabric weight: lighter fabrics or smaller transfers may only need a brief window, while heavier fabrics or larger designs benefit from a longer pre-press interval.

Choose fabrics with predictable shrinkage and stable color performance. Natural fibers like cotton respond differently than blends or synthetics, so test fabric–design–size combinations on swatches before full runs. This practice expands your library of size-specific DTF printing tips and strengthens your overall design optimization process.

6) Post-Press Care and Long-Term Durability Across Sizes

Finish and care instructions influence how customers perceive the durability of a size-varied DTF transfer. Provide clear washing and drying guidelines—ideally washing inside out in cold water and avoiding high heat—that reflect potential edge behavior observed in different sizes.

Durability hinges on proper post-press handling: removing protective sheets correctly, avoiding immediate high heat after pressing, and keeping the garment flat during cooling. Communicate size-specific care notes on product pages to reinforce the value of size-aware transfers and to support long-term performance, linking back to DTF design optimization principles and overall print quality across sizes.

Frequently Asked Questions

How does DTF transfer by size influence print area mapping across garments?

DTF transfer by size requires mapping the printable area for each garment size. Start by measuring the maximum printable zone for each product and create size-specific templates (S, M, L, XL). Use a safe bleed margin to avoid edge-to-edge issues and design scalable elements that resize cleanly. This approach aligns with DTF transfer sizes and is a core part of effective DTF printing tips.

What resolution and vector strategies optimize DTF transfer by size while preserving edge sharpness?

For DTF transfer by size, aim for 300 dpi at the final print size for raster art and use scalable vector artwork for text and shapes that will be enlarged or reduced. Create size-optimized variants and test swatches for each size to ensure legibility and contrast. This practice reflects DTF printing tips and DTF design optimization.

How should you set up size-based transfer settings for consistent results in DTF transfer by size, including heat press timing?

Develop size-based presets for heat, time, and pressure. Use separate profiles for small, medium, and large transfers and document the exact platen temperature, dwell time, and pressure. Include notes on fabric type and barrier sheets, and use this systematic approach as part of DTF transfer settings practices.

What are best practices for pressure uniformity and platen alignment with larger DTF transfer sizes?

Larger transfers require uniform pressure across the design. Use a larger platen or multi-step pressing, preheat the garment, and employ barrier sheets to distribute heat. If a larger platen isn’t available, press in sections while keeping temperature and alignment consistent. This relates to DTF transfer sizes and general DTF printing tips.

How do pre-press moisture control and fabric selection impact DTF transfer by size outcomes?

Pre-pressing removes moisture and reduces wrinkles that affect bonding, with time varying by size and fabric weight. Choose fabrics with predictable shrinkage and test size-specific combinations on swatches. This ties into DTF printing tips and DTF design optimization.

What finishing and care guidelines maximize durability for DTF transfer by size across products?

Provide clear post-press care instructions (wash inside out, cold water) and allow proper cooling before handling. Ensure complete curing of the adhesive and avoid aggressive handling that can lift edges on larger transfers. Durable results come from careful finishing, care guidance, and ongoing size-aware testing.

| Tip / Aspect | Key Point | Practical Takeaways |

|---|---|---|

| Tip 1: Size mapping and garment measurement | Define exact print areas per product; measure max printable area; map design to sizes; create scalable templates; use bleed/safe zones; keep critical elements away from edges. | Create size-specific templates (S, M, L, XL, etc.) or scalable vectors; apply a universal safe zone plus size adjustments; design for variations rather than one-size-for-all. |

| Tip 2: Quality and resolution per size | Artwork resolution and vector quality affect visual integrity; target ≥300 dpi final size; use scalable vectors for text/shapes; manage color density across sizes. | Generate size-specific variants; test print swatches for each size; maintain consistent color space (e.g., sRGB/Adobe RGB) and monitor density when scaling. |

| Tip 3: Size-based transfer settings | Heat, time, and pressure interact with transfer size; larger transfers may need longer dwell; smaller transfers may need different pressure; document size presets. | Use separate presets for small/medium/large; record platen temperature, time, pressure; note fabric, barrier use, and post-press care for repeatability. |

| Tip 4: Pressure and platen alignment for large sizes | Ensure uniform pressure to prevent ink gaps, waviness, or edge curling; use larger platen or multi-step pressing; preheat, distribute heat with barriers, and consider silicone pads. | If a large platen isn’t available, press in sections with consistent pressure/temperature; keep transfer flat and garment aligned to maintain size accuracy. |

| Tip 5: Pre-press, moisture control, and fabric selection by size | Moisture and fabric behavior affect bonding; pre-press duration varies by size/fabric weight; choose fabrics with stable shrinkage and color performance. | Test fabric–design–size combinations on swatches; build size-specific test results to guide future projects and margins. |

| Tip 6: Powdering, curing, and post-press handling by size | Powder application must be uniform across larger areas; adjust amount/distribution; allow cooling after press to prevent shifting; follow curing guidelines. | Add post-press checks for large transfers to ensure full bonding and edge integrity; tailor curing and cooling steps to size variations. |

| Tip 7: Finishing, care, and durability by size | Provide clear washing/drying instructions; size-specific care notes; durability depends on proper finishing, protective sheet removal, and controlled cooling. | Communicate size-aware care on product pages to reinforce quality and reduce returns; ensure long-term durability across sizes. |

Summary

This table summarizes the seven size-aware DTF transfer tips outlined in the base content, highlighting how size influences print area definition, design quality, transfer settings, pressure control, pre-press considerations, powdering/curing, and finishing care. Each tip provides practical actions to improve consistency and reduce rework when producing prints for different garment sizes.