When exploring the world of custom apparel, understanding DTF transfer size is crucial to your design’s success and overall aesthetic appeal. DTF transfers—an innovative printing technology—have gained traction due to their vibrant colors and exceptional quality. Selecting the appropriate transfer size not only influences the visual impact of your design but also contributes to its durability on fabric. This guide aims to shed light on how to size DTF transfers effectively, ensuring that your custom projects make a bold statement while maintaining high standards. With the right knowledge on choosing DTF transfer sizes, you will elevate your fabric creations and avoid common pitfalls associated with poor sizing.

In the realm of personalized clothing and fabric design, grasping the nuances of direct-to-film transfer dimensions is essential. The application of DTF printing methods brings a unique blend of aesthetic richness and quality to various fabrics. Understanding how to properly gauge transfer dimensions will ensure that your creations resonate visually and maintain their integrity over time. Whether you refer to them as custom apparel transfers or look into the subtleties of sizing patterns, mastering this aspect can significantly influence the outcome of your projects. Let’s unlock the secrets behind choosing the right size for optimal results in your custom designs.

Understanding DTF Transfers and Their Size Specifications

DTF transfers, or Direct to Film transfers, have revolutionized the way designers approach custom apparel. They involve printing designs onto a special film, which is then heat-pressed onto the fabric of choice. This method is widely praised for its ability to yield vibrant colors and intricate details, making it an ideal choice for various fabric types, including cotton, polyester, and blended materials. A critical component of successfully employing DTF technology is choosing appropriate transfer sizes, which directly impacts the overall aesthetic appeal of the final product.

When working with DTF transfers, the first aspect to consider is the dimensions. Understanding the standard sizes—from 8″x10″ for smaller applications on kids’ apparel to larger options like 12″x16″ for sweatshirts—will guide your decision-making. Selecting the right size not only enhances the visual appeal but also ensures the durability of the design, preventing issues such as cracking and peeling after repeated washes.

The Importance of Choosing the Right DTF Transfer Size

Choosing the right DTF transfer size is crucial for not just visual appeal but also for practical application reasons. A transfer that is too large can overwhelm the garment, detracting from the intended design elements. Conversely, a transfer that is too small may diminish the impact and visibility of your design. For instance, if you are creating a custom shirt, a standard medium size of 10″x12″ may be ideal for adult apparel, providing a good balance of presence without being overwhelming.

Moreover, proper sizing ensures that the transfer adheres securely to the fabric, extending the product’s lifespan. Transfers that exceed recommended sizes can experience issues of adhesion, resulting in designs that peel away after a few washes. Experts suggest keeping the transfer sizes under 30% of the garment area to maintain optimal performance, which is crucial for any successful custom apparel project.

Analyzing the Cost Implications of DTF Transfer Sizes

Budgeting for custom apparel projects often involves considering the costs associated with DTF transfers. As a rule of thumb, larger transfers not only require more material but also incur higher production costs. For small businesses or startups, understanding the relationship between transfer size and pricing can aid in managing expenses effectively. Analyzing market rates for various transfer sizes can provide insights into pricing strategies that maximize profit margins while maintaining quality.

When planning your custom apparel production, it’s essential to account for both the initial investment in DTF transfers and the potential returns from selling those items. By selecting the most appropriate transfer sizes for your designs, you can create products that appeal to your target market while ensuring you stay within budget. This efficient approach to size choice not only aids in controlling costs but also helps in establishing a reputation for high-quality custom apparel.

Quality and Durability: The Role of Transfer Size

Quality and durability are paramount in the world of custom apparel. One of the main reasons selecting the proper DTF transfer size is critical lies in its effect on these two factors. Overly large transfers may not adhere properly, leading to detrimental effects such as cracking and peeling over time. Correct sizing promotes better adhesion to various fabrics, particularly during the heat-pressing phase, ensuring that the final product withstands repeated washings.

In essence, paying attention to transfer size can lead to long-lasting designs that hold their vibrancy and integrity over time. When designing custom items, the balance between size, quality, and durability should guide each decision you make to enhance customer satisfaction and build brand loyalty. Understanding how to size DTF transfers accurately plays a pivotal role in achieving this balance.

Key Trends Influencing DTF Transfer Size Selection

The DTF printing industry is evolving rapidly, with new trends influencing how designers approach size selection for their transfers. Recently introduced advanced ink formulas and improved transfer films have opened up new possibilities for customization, providing designers with better options for vibrant performance and durability. Additionally, eco-friendly options are gaining traction, prompting designers to consider sustainability when choosing sizes and materials.

As consumer preferences shift toward sustainable practices, understanding these trends can inform your choices regarding DTF transfer sizes. Opting for eco-friendly materials while considering size constraints can lead to new market opportunities, particularly among environmentally-conscious consumers seeking unique and sustainable apparel solutions. Keeping your finger on the pulse of these trends will help keep your designs relevant and appealing.

Tips for Measuring and Sizing DTF Transfers Effectively

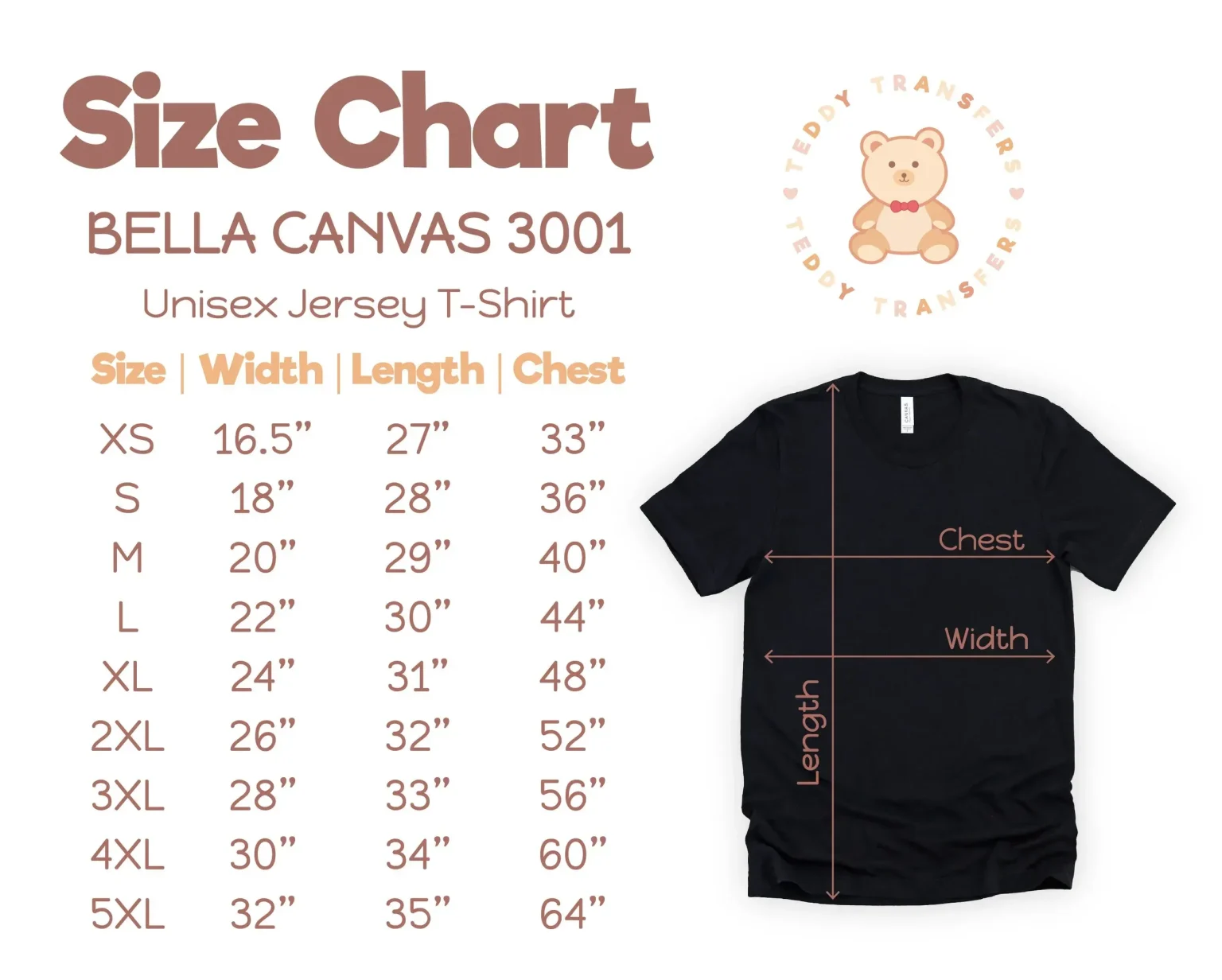

Measuring and sizing DTF transfers can be a daunting task if not approached methodically. One of the first tips is to measure the area of the garment where the transfer will be applied. Creating a visual mock-up of the planned design on garment specifications can provide a clearer perspective on ideal dimensions. Utilizing visual aids, such as templates or sizing charts, can ensure that you achieve the desired effect with your custom designs.

Furthermore, it’s essential to account for the intricacies of each design. More complex designs may benefit from slightly larger sizes to capture intricate details reflectively. Conversely, simpler designs may work better within restricted dimensions. Keeping these considerations in mind when sizing DTF transfers can significantly enhance the quality and visual appeal of your final product.

Frequently Asked Questions

What is the best way to choose the right DTF transfer size for my custom apparel?

Choosing the right DTF transfer size involves understanding the garment area and the design’s visual impact. Generally, you want the transfer to be no larger than 30% of the garment’s area for optimal adherence and durability. Pay attention to garment types too; small sizes (8″x10″) fit well on kids’ shirts, while larger sizes (12″x16″) are better for sweatshirts.

How does the size of DTF transfers affect the durability of the design?

The size of DTF transfers directly impacts their durability. Transfers that are too large can lead to cracking and peeling after washing, while appropriately sized transfers adhere better and last longer. Ideally, keep the transfer size within 30% of the garment area to enhance the design’s longevity.

What are the common sizes available for DTF transfers and their applications?

Common DTF transfer sizes include 8″x10″, 10″x12″, and 12″x16″. Smaller sizes, like 8″x10″, work well for items with limited space, such as caps or pockets. Medium sizes (10″x12″) suit adult t-shirts, and larger sizes (12″x16″) are ideal for hoodies and elaborate designs.

Why is it important to consider the size when selecting DTF transfers for printing technology?

Considering the size of DTF transfers is crucial as it affects both the visual appeal and the integrity of the design. A well-sized transfer enhances the garment’s look, while an oversized transfer can compromise durability. Matching the transfer size to the garment ensures quality results.

What impact does DTF transfer size have on production costs in custom apparel?

DTF transfer size can significantly impact production costs. Larger transfers typically incur higher material and printing costs, so it’s essential for businesses to plan accordingly. Understanding how transfer size correlates with pricing helps in budget management for custom garment production.

How can I ensure that my DTF transfers are the right size for specific garment types?

To ensure DTF transfers are the right size, consider the garment’s area, type, and the design’s complexity. For instance, use smaller transfers for fitted garments and larger sizes for loose-fit items. It can also be beneficial to refer to sizing guides from reputable DTF printing resources.

| Key Points | Details |

|---|---|

| Understanding DTF Transfers | DTF transfers use a printing technique to apply designs to fabrics using heat and pressure, known for vibrant colors and quality. |

| Why Size Matters | Choosing the right size affects visual appeal, quality, and durability of the transfer. |

| Common Sizes | Common sizes: 8″x10″ for kids’ shirts, 10″x12″ for adult t-shirts, 12″x16″ for sweatshirts. |

| Quality and Durability | Proper sizing ensures better adhesion and longevity, preventing cracking and peeling. |

| Cost Implications | Larger transfers typically have higher production costs; budget planning is essential. |

| New Trends in DTF Technology | Recent advancements include better ink formulations and eco-friendly options. |

Summary

DTF transfer size is a crucial element in ensuring that your custom designs achieve the desired visual impact while maintaining quality and durability. Understanding how to select the right DTF transfer size is essential in maximizing the appeal of your projects. By taking into account factors such as garment type and design intricacy, you can choose a transfer size that not only enhances the aesthetic of your fabric products but also contributes to their longevity. With ongoing advancements in DTF technology, selecting the appropriate size becomes even more critical, allowing you to stay ahead in a competitive market.