DTF transfers by size are a crucial consideration in the booming arena of custom apparel printing. As this innovative method of Direct to Film (DTF) printing continues to gain traction, understanding the implications of design size has never been more important. With DTF printing, you can unleash vibrant colors and intricate designs on a variety of fabrics, but choosing the right dimensions for your artwork ensures a flawless fit and top-notch quality. In this guide, we’ll delve into size considerations for DTF, including how to create artwork fit for DTF and ensuring material compatibility, so you can deliver standout pieces that resonate with your audience. Join us as we explore the best practices to optimize your DTF transfer designs and elevate your custom clothing line.

In the realm of custom clothing production, Direct to Film printing has become an invaluable tool for creators. Understanding DTF transfers in relation to dimensions is essential for achieving outstanding results in your fabric printing endeavors. This process not only allows for a rich display of color and detail but also emphasizes the importance of proper sizing to ensure that your designs translate well onto various materials. As we analyze the intricacies of artwork fitting and the essential aspect ratio considerations, we will highlight the vital connection between size and quality in DTF applications. Preparing to perfect your custom apparel projects means mastering the nuances of DTF transfer dimensions and their impact on end results.

The Basics of DTF Printing and Artwork Sizing

Direct to Film (DTF) printing has revolutionized the custom apparel industry by allowing intricate designs to be transferred onto various fabrics seamlessly. Understanding how to properly size your artwork is essential for achieving optimal quality in your prints. One of the foundational practices in DTF printing is to start your design at a high resolution, ideally 300 DPI. This ensures that even when resizing, the details remain crisp and vibrant, contributing to a finished product that stands out in both detail and color.

Moreover, when preparing your artwork, it’s paramount to consider the proportionate sizing of your designs. Keeping a careful balance between width and height not only preserves the aesthetic appeal of your artwork but also ensures that the final output looks professional and well-crafted. By adhering to these essential sizing principles, you can create stunning apparel that showcases your unique designs.

Sizing Options for Optimal DTF Transfers

When it comes to DTF transfers, having the right sizing options can drastically improve the final outcome of your printed apparel. Firstly, it’s important to understand that smaller designs may require additional considerations, such as leaving a margin of about one to two inches around your artwork. This strategy allows the design to breathe on the fabric, preventing any awkward cutoff that might occur during the transfer process.

Additionally, it’s crucial to explore the possibilities of adjustable dimensions according to the specific items you are printing on. Each item, whether it be a t-shirt, hoodie, or tote bag, has its own print area limitations. By measuring correctly and experimenting with various design sizes, you can find the perfect fit that not only enhances visibility but also makes the overall design more appealing.

The Impact of Frame and Border on DTF Transfers

One often-overlooked aspect of DTF printing is the influence that frames and borders can have on your design’s aesthetic. When sizing your prints, incorporating a border can provide a much-needed separation between the artwork and the edges of the fabric, enhancing focus on the design itself. This stylistic choice improves the visual impact and can make your prints look more polished and professional.

That said, the width of the border should be carefully calculated to avoid overwhelming the artwork. Whether you choose a minimalist frame or a more elaborate border design, ensuring it fits well within the dimensions of the fabric is essential. By maintaining these considerations, your apparel can transform from basic to beautifully crafted, effectively highlighting the art in custom printing.

Measuring Your Fabric for Accurate DTF Transfer Sizes

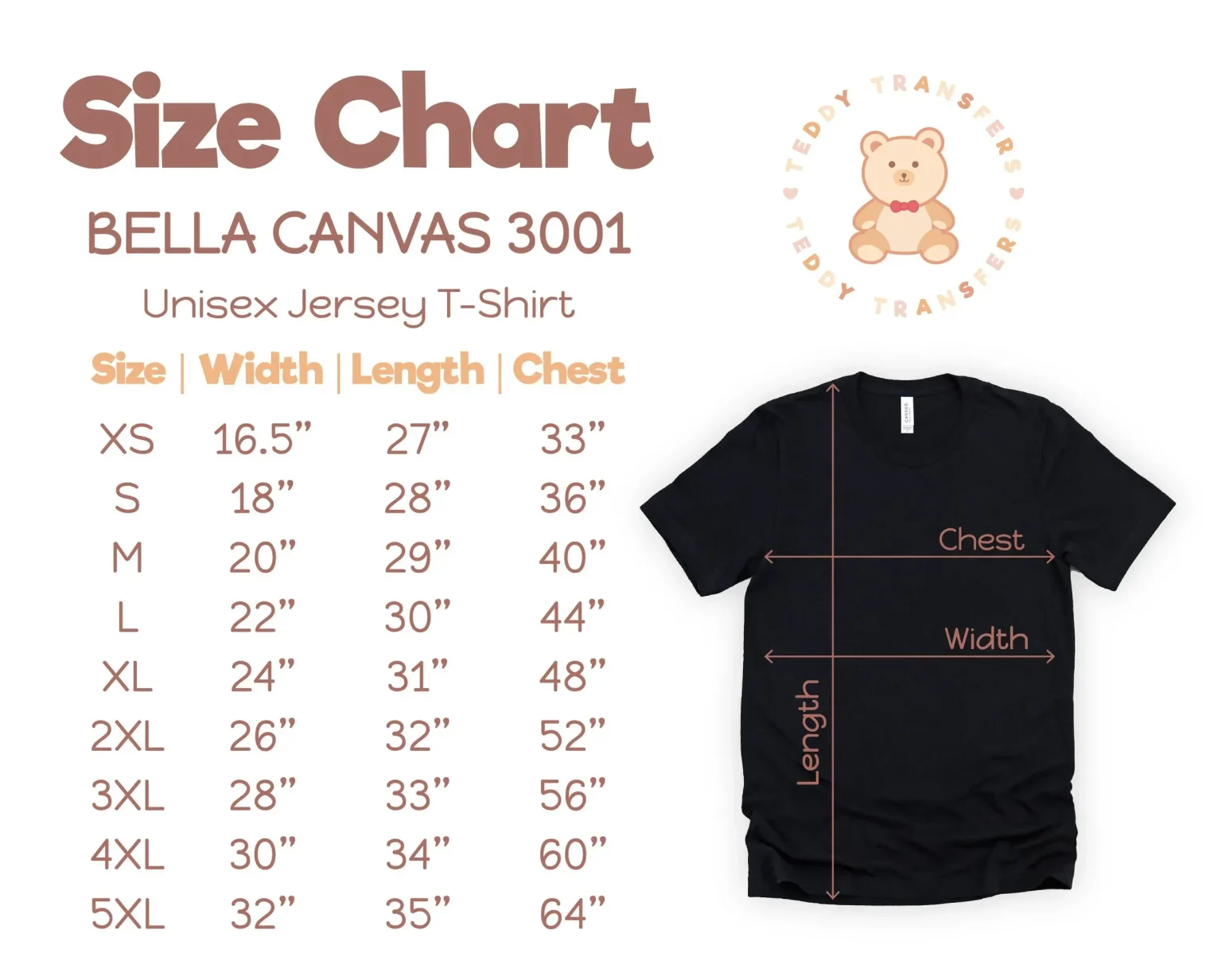

Accurately measuring the fabric where your DTF transfer will be applied is critical to achieving the desired outcome. Before finalizing your design, take a moment to use a flexible measuring tape to record the dimensions of the print area on the garment. For example, when working with a T-shirt, the standard print area is typically located on the front side, making it straightforward to determine the suitable size for your design.

However, different garment styles will have unique sizing requirements based on their construction and intended fit. By taking the time to measure each piece accurately, you can create a tailored approach to sizing that enhances both the look and feel of your custom apparel. The precise fit ensures that your designs are front and center, drawing attention and admiration.

Maintaining Aspect Ratio in DTF Design Sizing

One of the key considerations when resizing your artwork for DTF transfers is maintaining the aspect ratio. This means that whether you’re enlarging or shrinking your design, its proportions should remain constant to avoid any distortion. Modern design software typically includes a feature that locks the aspect ratio when adjusting dimensions. This ensures that your artwork retains its proportional relationships and overall integrity, making for a more visually impactful final product.

Failing to maintain this ratio can lead to unexpected outcomes, such as stretched or squished designs that may not represent your original vision. It’s vital to familiarize yourself with your graphic design software capabilities, taking full advantage of these tools to ensure that the appearance of your artwork is preserved through any resizing process.

Best Practices for DTF Printing Size Testing

Conducting test runs is one of the best practices you can adopt when preparing for DTF printing. Creating sample prints of your design in varying sizes allows you to see how they translate onto the actual fabric. This process not only helps in identifying the ideal dimensions but also aids in assessing the quality of detail, color vibrancy, and overall appeal of the print.

Engaging in this practice can help reduce material waste and ensure that you are making informed decisions before moving on to the final production. Testing various sizes can reveal how different dimensions work with the chosen material, allowing you to fine-tune your designs based on practical outcomes.

Frequently Asked Questions

What are the size considerations for DTF transfers when designing artwork?

When designing artwork for DTF transfers, it’s crucial to consider the size of your print. Aim for a high resolution of 300 DPI to ensure crisp details and leave a 1-2 inch border around smaller designs to enhance their visual appeal. Additionally, accurately measuring your fabric’s print area is essential to avoid size mismatches.

How does fabric type affect the size of DTF transfers?

Fabric type significantly influences the sizing of DTF transfers. Stretchy materials like spandex may require smaller transfers to prevent cracking, while rigid fabrics, such as canvas, can accommodate larger designs without compromising print integrity. It’s essential to choose a size that complements the fabric’s characteristics.

What is the importance of maintaining aspect ratio in DTF transfers?

Maintaining the aspect ratio when resizing designs for DTF transfers is crucial to avoid distortion. Ensure that width and height increase or decrease proportionally. Most graphic design software allows you to lock the aspect ratio to simplify this process, ensuring your artwork remains visually appealing.

Can I customize the size of DTF transfers based on my printing needs?

Yes, DTF transfers can be easily customized based on your printing needs. Modern printing software often includes features that suggest optimal print sizes tailored to material and design complexity. Additionally, customizable templates can help streamline the sizing process for common print jobs.

What are the recommended sizing practices for DTF transfers on custom apparel?

For custom apparel, it’s recommended to conduct test prints to determine the best size for your design. Start with different dimensions to see how they look on your fabric. Keep in mind high resolution (300 DPI), adequate borders, and fabric measurements to achieve the best quality in your DTF transfers.

How can I improve the quality of DTF transfers by adjusting design size?

Improving the quality of DTF transfers involves carefully adjusting the design size to match the fabric’s print area. Ensure your design is appropriately sized—neither too large nor too small—considering the fabric’s stretch and texture. Conducting test prints with varying sizes can help identify the ideal fit for vibrant, quality results.

| Aspect | Key Points |

|---|---|

| Importance of Sizing | The size of your design greatly influences print quality and visual appeal. |

| High Resolution | Artwork should ideally be created at 300 DPI for crisp details. |

| Border Considerations | A 1-2 inch border is suggested for smaller designs to enhance visibility. |

| Measuring Fabric | Accurate fabric measurements are crucial for determining design size. |

| Aspect Ratio | Maintain proportional width and height to prevent distortion. |

| Material Compatibility | Different fabrics may require different sizing approaches. |

| Test Prints | Conduct test runs with varying dimensions for optimal appearance. |

| Recent Advancements | New software features help recommend optimal sizing based on material. |

Summary

When considering DTF transfers by size, it is essential to understand that the right size can drastically enhance the outcome of your custom apparel projects. Proper sizing not only impacts the visual quality of your prints, ensuring that designs are vibrant and detailed, but it also maximizes the compatibility with various fabrics, preventing issues such as distortion or distortion during application. Evaluating factors such as resolution, border preferences, and measuring accurately will ultimately lead to better results, fewer errors, and improved production efficiency in your DTF printing endeavors.