UV DTF transfers are at the forefront of an exciting evolution in custom merchandise, reshaping how businesses approach apparel and product customization. This innovative printing technology leverages ultra-violet cured inks to create stunning, high-quality designs that adhere brilliantly to a multitude of surfaces, from fabrics to hard materials like plastic and metal. As businesses delve into the benefits of UV DTF, they’ll uncover its impressive versatility, durability, and vibrant color output, which can elevate their product offerings. Furthermore, as sustainability becomes a paramount concern, the eco-friendly aspects of UV DTF printing provide an appealing option for environmentally-conscious consumers. By integrating UV DTF transfers into their operations, companies can not only enhance their merchandise but also align with evolving market demands.

Exploring the world of direct-to-film transfers, or DTF printing, reveals a cutting-edge approach to creating personalized products that captures the attention of consumers. This state-of-the-art printing method utilizes UV technology to deliver eye-catching visuals and unmatched longevity across various materials, making it an essential tool for businesses focused on customizing their merchandise. The advantages of DTF printing extend beyond simple design capabilities to include vibrant color reproduction and sustainable printing practices that resonate with today’s eco-aware buyer. With the ongoing demand for unique products, leveraging this advanced printing technology allows companies to not only meet consumer preferences but also stand out in a competitive market. Embracing these innovative DTF methods positions brands to succeed in the ever-evolving landscape of custom merchandise.

Understanding UV DTF Transfers: A Printing Revolution

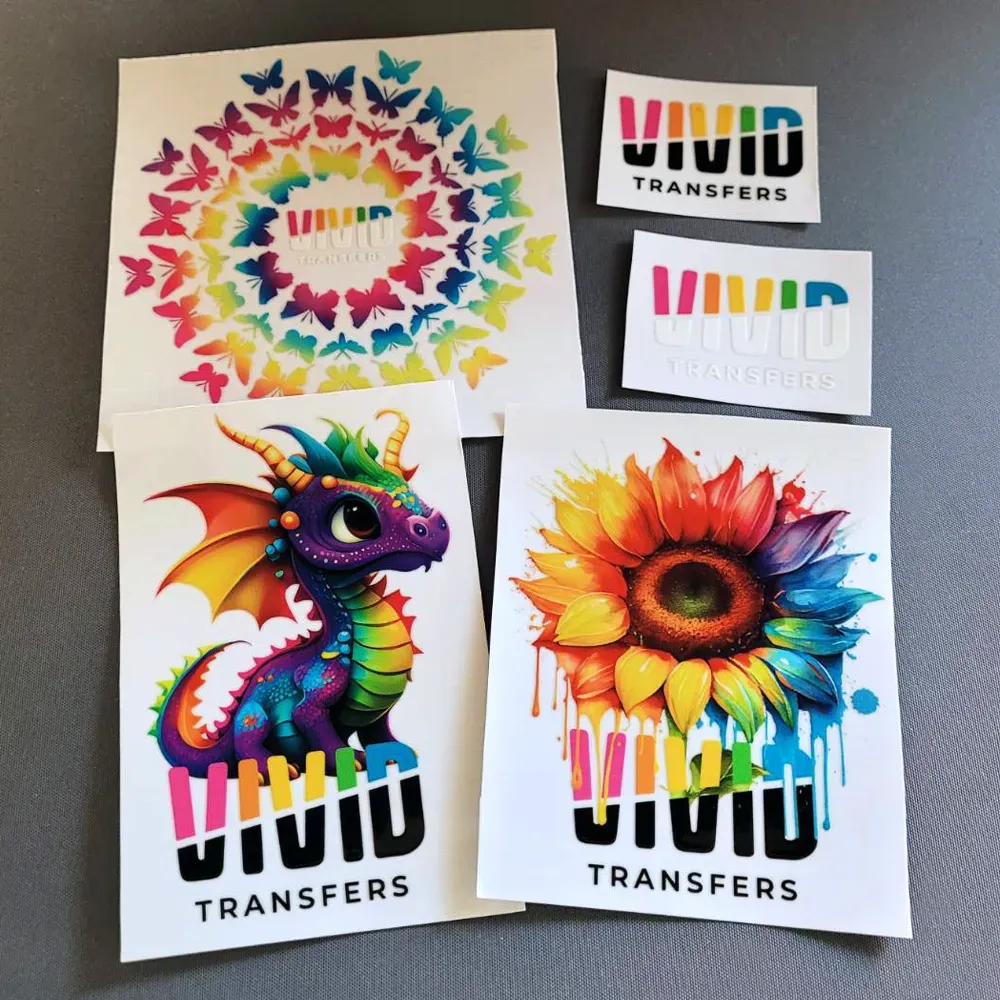

UV DTF transfers leverage cutting-edge printing technology that allows businesses to produce stunning designs on a variety of surfaces. This method involves printing images onto a specialized film using UV-cured inks, which are then transferred onto the desired substrate. The ability to print on materials such as textiles, plastics, and metals increases the versatility of these transfers, making them particularly appealing for custom merchandise. Brands can cater to specific demographic needs by employing UV DTF, thus opening doors to new market segments.

Notably, the commercial use of UV DTF transfers extends beyond fashion apparel to various promotional items and accents. Companies can create eye-catching mugs, phone cases, or even outdoor gear that showcases creative designs. As businesses explore this technology, they discover not only a reliable method of production but also a way to diversify their offerings and better engage with their market.

The Benefits of UV DTF Transfers for Custom Merchandise

There are several benefits to using UV DTF transfers for custom merchandise. Firstly, they are incredibly durable, making them suitable for products that see frequent use or washing, such as promotional wearables or outdoor gear. Compared to traditional printing techniques, prints produced through UV DTF are resistant to scratching, fading, and wear, which enhances the longevity of graphical designs. The resilience of these prints helps businesses maintain their reputation by ensuring that the products delivered to customers retain their quality over time.

Additionally, the vibrant color quality provided by UV inks utilized in DTF printing cannot be overlooked. The inks produce bright, eye-catching designs that enhance the final product’s visual appeal, thus attracting consumers in a bustling marketplace. For graphic-heavy merchandise that relies on fine details, this color integrity is crucial in communicating brand identity and values to targeted consumers.

Eco-Friendly Aspects of UV DTF Printing

With sustainability becoming a pivotal factor for consumers, the eco-friendly nature of UV DTF printing positions it as an attractive option among various printing methodologies. Many manufacturers have developed UV-curable inks that contain significantly lower levels of volatile organic compounds (VOCs) than traditional solvent-based inks. This shift towards greener options not only aligns with environmental regulations but also resonates strongly with eco-conscious consumers, adding a layer of value to products created utilizing this method.

Embracing UV DTF technology allows businesses to communicate their commitment to sustainability, which can build stronger brand loyalty among consumers who prioritize environmentally responsible practices. By offering products that leverage this sustainable printing technology, brands can appeal to a growing segment of the market dedicated to supporting eco-friendly initiatives.

Customization and Market Trends in UV DTF Production

As trends in consumer behavior evolve, the demand for customization in merchandise grows. UV DTF transfers provide businesses with the tools they need to meet these expectations. The technology enables companies to create personalized products at scale, catering directly to individual customer desires. This seamless capability to produce unique merchandise enhances customer connection and loyalty, especially among younger demographics who value individual expression.

The customization potential of UV DTF not only differentiates businesses in a crowded marketplace but also aligns with the predominant trends permeating e-commerce. Retailers are increasingly embracing strategies that focus on providing personalized shopping experiences. As they make use of DTF printing, companies can tap into the expanding demand for customized goods while maintaining competitive pricing structures, thus maximizing their sales effectiveness.

Challenges Businesses Face with UV DTF Transfers

While UV DTF transfers present numerous advantages, companies contemplating this technology must acknowledge associated challenges. The initial investment in printing equipment can be substantial, and without careful budgeting or strategic planning, it may pose a financial burden, especially for small businesses. Balancing the potential returns against these upfront costs becomes critical in the decision-making process.

Moreover, transitioning to new technology like UV DTF requires training and adaptation. Business owners and staff may face a learning curve as they become familiar with the operational intricacies of the equipment and printing processes. Consequently, businesses must be prepared to invest time in training and experimentation to fully harness the capabilities and benefits of UV DTF transfers.

The Future of Custom Merchandise with UV DTF Technology

The future of custom merchandise hinges on innovation, and UV DTF technology is at the forefront of this movement. As consumer interests grow towards personalized and unique products, businesses that adopt UV DTF are poised to thrive. The tanning of operational costs associated with traditional printing techniques gives way for smaller players in the market to explore new horizons, finding their niche by producing distinctive merchandise.

In conclusion, as e-commerce continues to expand and the demand for originality in products rises, UV DTF transfers will likely play a pivotal role in shaping the landscape of custom merchandise. By capitalizing on this innovative technology, businesses can remain competitive while profoundly impacting their market presence.

Frequently Asked Questions

What are UV DTF transfers and how do they work in custom merchandise?

UV DTF transfers, or UV Direct to Film transfers, utilize UV-cured ink to print vibrant designs on a special film. This technology allows for high-quality images to be transferred onto various substrates such as textiles, plastics, and metals, making it ideal for producing custom merchandise.

What are the main benefits of UV DTF transfers for custom merchandise production?

The benefits of UV DTF transfers include their versatility in printing on multiple materials, durability against wear and tear, and vibrant color reproduction. These factors collectively enhance the quality of custom merchandise and attract consumers seeking unique products.

How do UV DTF transfers compare to traditional printing technologies?

UV DTF transfers offer several advantages over traditional printing methods, including faster production speeds, superior durability, and the ability to print on a wider range of materials. This makes UV DTF an increasingly popular choice for businesses looking to create high-quality custom merchandise.

Are UV DTF transfers an eco-friendly option for printing custom merchandise?

Yes, many UV inks used in DTF printing contain lower levels of volatile organic compounds (VOCs) compared to traditional solvent-based inks, making UV DTF transfers a more sustainable printing solution. This eco-friendliness appeals to environmentally conscious consumers.

What market trends are influencing the adoption of UV DTF transfers in custom merchandise?

The growing demand for custom merchandise, particularly in e-commerce, is a significant trend driving the adoption of UV DTF transfers. Innovations in printing technology are also making it more accessible for small businesses to integrate this advanced printing method into their operations.

What challenges might businesses face when adopting UV DTF transfers for custom merchandise?

Businesses may face challenges such as high initial equipment costs and a learning curve associated with new printing technology. Careful budgeting and training are essential for successful integration of UV DTF transfers into existing operations.

| Key Feature | Details |

|---|---|

| Versatility | Allows printing on a wide range of materials including textiles, plastics, and metals for diverse products. |

| Durability | Resistant to scratching, fading, and wear, making it suitable for items exposed to harsh conditions. |

| Vibrant Colors | Uses UV inks for bright and sharp designs that attract consumers. |

| Eco-Friendly Options | Manufacturers are creating inks with fewer VOCs, appealing to environmentally conscious consumers. |

| Market Trends | Increased demand for custom merchandise and recent innovations are driving adoption. |

| Customization Implications | Enables businesses to offer personalized products that enhance customer engagement and loyalty. |

| Challenges | Initial equipment costs and a learning curve may hinder immediate adoption. |

Summary

UV DTF transfers represent a groundbreaking advancement in custom merchandise production, offering a plethora of benefits for businesses looking to elevate their product offerings. This innovative printing technology not only promotes versatility and durability but also provides vibrant color reproduction and eco-friendly options. As the custom merchandise market continues to expand, the application of UV DTF transfers becomes increasingly critical for companies aiming to thrive in a competitive landscape. By considering potential challenges and investing strategically, businesses can successfully harness the power of UV DTF transfers to meet consumer demands and differentiate themselves in the marketplace.