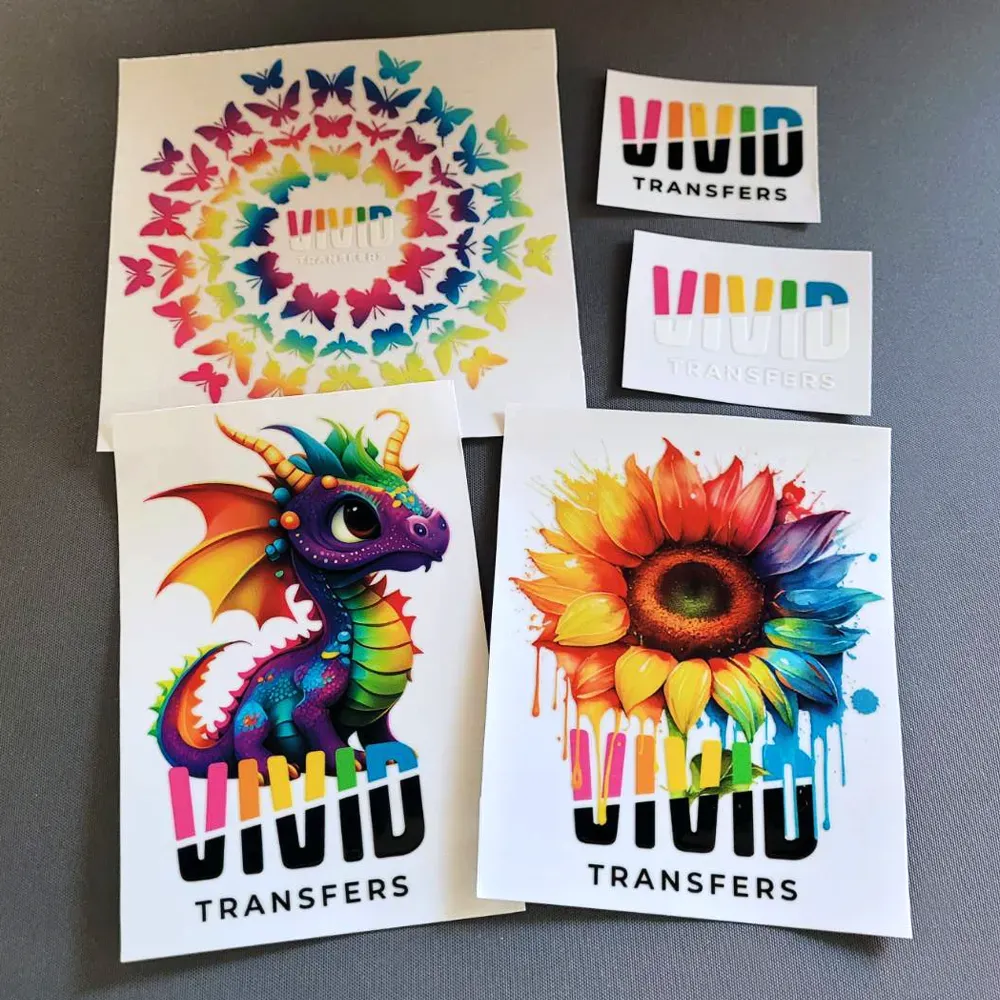

UV DTF Transfers are revolutionizing the world of apparel printing by combining cutting-edge technology with traditional practices to create stunning, durable designs. This innovative printing method utilizes ultraviolet light to cure inks almost instantaneously, allowing for vibrant colors and intricate patterns on a multitude of materials. As the demand for unique and customized clothing continues to grow, DTF printing stands out for its versatility and cost-effectiveness, making it a favored choice among businesses striving to differentiate themselves in a competitive market. Notably, UV printing technology not only enhances the quality of prints but also promotes sustainable practices in the apparel industry by reducing waste associated with traditional methods. In this blog post, we will delve into why UV DTF transfers are seen as the future of apparel transfers, exploring their benefits and the trends that drive their adoption.

Introducing the exciting realm of Direct to Film (DTF) transfers, particularly through the innovative UV DTF technique, showcases a significant leap in apparel printing technologies. This advanced method leverages direct-to-film technology and ultraviolet curing to enhance the printing process, offering superior quality and efficiency. By embracing this modern approach, businesses can produce high-quality, long-lasting apparel designs tailored to meet the demands of a diverse customer base. The unique capabilities of UV DTF printing not only improve workflow efficiency but also cater to the growing trend of eco-conscious production, making it a sustainable choice for print shops. As we explore further, you’ll discover how this evolution in UV printing technology is reshaping the landscape of apparel customization.

The Mechanism Behind UV DTF Transfers

UV DTF transfers employ a unique mechanism that distinguishes them from traditional printing methods. The process begins with special UV inks that are applied to a film, which then undergoes curing through ultraviolet light. This immediate curing not only accelerates the printing process but also enhances the vibrancy and longevity of colors. Unlike the conventional DTF printing, which relies on heat to set the ink, UV DTF allows for immediate production turnaround, making it ideal for businesses aiming to meet tight deadlines.

Furthermore, the versatility of UV DTF printing extends the potential for application on various substrates. From apparel to hard goods, it opens a realm of possibilities that traditional DTF cannot cater to effectively. Print businesses can explore opportunities in promotional items, custom merchandise, and even industrial applications, thus reaching diverse consumer markets. The adaptability of UV DTF transfers enhances creative potentials for designers, allowing them to experiment with textures, finishes, and layering without the constraints of traditional methods.

Comparative Analysis: UV DTF vs. Traditional DTF Printing

When evaluating UV DTF printing against traditional DTF methods, several critical differences emerge that underline the advantages of the former. Traditional DTF printing relies heavily on heat transfer, limiting its applications to textile materials and potentially leading to less vibrant colors and less durability. In contrast, UV DTF allows for the use of a broader range of substrates, including hard materials, which significantly amplifies its usability in the market.

Additionally, UV DTF’s instant curing process greatly reduces production time, which is becoming increasingly important in today’s fast-paced retail environment. Companies embracing UV DTF technology can offer shorter lead times for custom orders and diverse product offerings, enabling them to stay competitive. This technological edge not only positions UV DTF transfers favorably in the apparel printing market but also opens doors for creative innovation and expansion into non-apparel sectors.

Why Durability Matters in Apparel Printing

Durability is a crucial aspect when it comes to apparel printing, as it directly impacts customer satisfaction and repeat business. In the realm of UV DTF transfers, the durability of the prints is exemplary; they are resistant to fading, cracking, and peeling, even after multiple washes. This impressive resilience not only extends the life of the printed apparel but also fosters customer trust in the brand, as they know they are investing in high-quality products.

Moreover, with the rise of activewear and everyday apparel that endure frequent use, the durability provided by UV DTF transfers positions them as a preferred choice for brands looking to cater to quality-conscious consumers. The ability to create long-lasting prints without sacrificing vibrancy adds significant value, allowing apparel brands to offer products that withstand the test of time and usage, thus resulting in increased customer loyalty.

Environmental Benefits of UV DTF Printing Technology

Embracing sustainability is increasingly essential for brands in the apparel industry, and UV DTF printing technology aligns seamlessly with this shift. Unlike traditional printing methods that may utilize harmful solvents and wasteful production processes, UV DTF printing promotes a more eco-friendly approach. By using UV inks that cure quickly with UV light, it minimizes the environmental impact associated with chemical emissions and waste, appealing to environmentally-conscious consumers.

In addition, the print-on-demand capabilities of UV DTF technology help mitigate waste by allowing brands to produce items based on actual consumer demand rather than overproduction. This strategy not only reduces excess inventory but also aligns with sustainable business practices, making it an attractive option for brands committed to responsible production methods. The integration of eco-friendly practices through UV DTF printing could become a defining characteristic for brands aiming to differentiate themselves in a competitive market.

Cost Efficiency and UV DTF Transfers in Apparel Production

Cost efficiency is a cornerstone of successful business operations, and UV DTF printing exemplifies this principle within the apparel printing industry. By streamlining the workflow—from printing directly onto various substrates to immediate curing—companies can expect substantial savings on production costs. The minimized need for secondary processes not only cuts down on labor costs but also reduces material waste, creating a more sustainable ecosystem for apparel production.

For small and medium-sized enterprises, the cost benefits are particularly pronounced. With lower overheads and enhanced operational efficiency, these businesses can compete more effectively with larger corporations. Additionally, the affordability of UV DTF transfers allows them to explore new product lines and target niche markets without incurring prohibitive costs, thus expanding their customer base while maintaining profitability.

Future Trends and Market Potential for UV DTF Printing

The apparel printing market is on the brink of transformation, with UV DTF printing emerging as a driving force for future trends. As consumer demand shifts towards personalization and customization, businesses that harness the power of UV DTF technology will likely see a significant uptick in market relevance. The increasing inclination for unique fashion statements among consumers, driven by social media influences and individualistic trends, positions UV DTF printing technology as a key enabler of personalized apparel.

Moreover, market studies project substantial growth in the UV printing technology sector as it continues attracting interest from various industries beyond apparel. This technology’s potential for scalability and versatility opens doors for innovations across the printing landscape, presenting opportunities for diversification and expansion into other markets such as home décor, promotional products, and beyond. Companies that adapt to these emerging trends will not only stay ahead of the competition but also redefine the printing standards for the future.

Frequently Asked Questions

What are UV DTF Transfers and how do they differ from traditional DTF printing?

UV DTF Transfers utilize ultraviolet light to cure inks instantly, providing vibrant colors and durability. Unlike traditional DTF printing, which requires heat for curing, UV DTF can print on a wider variety of materials, including textiles, metals, and plastics, making it a versatile option in apparel printing.

What are the benefits of using UV DTF printing for apparel transfers?

UV DTF printing offers numerous benefits for apparel transfers, including higher durability against fading and cracking, faster drying times due to instant curing, and the ability to print on various substrates. This makes it ideal for custom apparel and promotional items while ensuring cost-effectiveness and efficiency.

How does UV printing technology enhance the process of apparel printing?

UV printing technology enhances apparel printing by using UV-cured inks that react quickly to light, allowing for immediate adhesion and high-resolution prints. This technology minimizes drying times and increases production speed, making it possible to handle large orders efficiently, which is crucial for competitive apparel markets.

Can UV DTF Transfers be used on different materials for apparel printing?

Yes, UV DTF Transfers are highly versatile and can be used on various materials such as textiles, plastics, metals, and wood. This adaptability allows brands to expand their product offerings, catering to a wide range of customer needs and preferences in the apparel and promotional items market.

Why is durability important in UV DTF Transfers for the apparel industry?

Durability is crucial in UV DTF Transfers because high-performance prints can withstand multiple washes without fading, peeling, or cracking. This resilience is essential for maintaining quality apparel, ensuring customer satisfaction, and supporting brand loyalty in a competitive market.

How does UV DTF Printing contribute to sustainability in apparel production?

UV DTF Printing contributes to sustainability by utilizing UV inks that are less harmful than traditional solvent-based inks, thereby reducing environmental impact. Additionally, the print-on-demand model reduces waste from overproduction, aligning with the growing consumer preference for eco-friendly products in the apparel industry.

| Key Points | Details |

|---|---|

| Technological Advancements | UV DTF printing leverages advanced technology to enable faster, more efficient printing on multiple substrates with reduced drying times. |

| Versatility of Applications | Ability to print on diverse materials allows customization for t-shirts, promotional items, and niche markets. |

| Durability & Quality | High-performance prints that are resistant to fading, cracking, and peeling after multiple washes. |

| Environmental Considerations | Utilizes eco-friendly UV inks, reducing harmful chemicals and supporting sustainable production. |

| Cost-Effectiveness | Streamlined operations lead to lower costs, beneficial for small businesses looking to grow. |

| Market Growth and Future Outlook | Increasing demand for on-demand and personalized apparel drives growth in the UV DTF market. |

Summary

UV DTF Transfers are revolutionizing the apparel printing industry with their innovative approach to printing technology. By integrating ultraviolet light for immediate ink curing, UV DTF delivers vibrant colors and exceptional prints on a wide array of substrates. Its versatility allows businesses to serve diverse markets, while the durability of the prints ensures long-lasting quality. Furthermore, its eco-friendly nature aligns with the modern consumer’s push for sustainability, making it a compelling choice for responsible production practices. As the demand for personalized and on-demand apparel continues to rise, businesses that adopt UV DTF Transfers will not only improve their operational efficiencies but also secure a competitive edge in a constantly evolving market.